SEED TECHNOLOGlES CORP., LTD.

Seed technologies corp., Ltd., was established in 2006, located in zhuzhou (China), is a high-tech developer, manufacturer, and distributor of superior wear resistant parts, tool assembly and equipment for oil and gas, areospace, valve and pumps industry.

In 2013, Aseeder corporation was invested by seed as a houston based company dedicated for sales and customer support in north America market.

In 2015, Seed technologies(Beijing) was founded as a material R&D center, With passion and creativity, Seed team has reached advanced international standards in 3D printing of refractory metal alloys and high temperature composite material. Such technology has been evaluated and highly recognized by the expertise from China Association of Science and Technology. At the same time, Seed is the very first inventor worldwide of 3D printing (additive manufacturing) of refractory metal/high temperature metal matrix composites with multiple constituents. This invention opens a new era of global carbide technology and will exert profound impact in the field of powder metallurgy and its applications.

Major product lines

· Wear resistant carbide components via powder metallurgy technique

· Hardfacing (oxy-acetylene spray, pta, hvof, etc. ) and surface enhancement (phosphating, boronizing, etc. )

· High-precision machining of metals (s. Steel, carbon steel, inconel 718, etc. )

· Additive manufacture

The products and technologies from seed (aseeder) have been widely applied in the fields of oil & gas, chemical engineering, subsea, nuclear power and aerospace industries. Mainly used in harsh operating conditions include severe abrasion, erosion, corrosion, high temperature, high pressure and strong impact. Our major clients are fortune 500 companies. Seed is the leading export enterprise in China of wear-resistant cemented carbide products and the related high-precision machining techniques.

Ever since the company was founded, ASEEDER keeps pursuing growth and development based on the core business philosophy of innovation, determination, dedication to details and intelligence manufacturing. Seed is specialized in the manufacture and high-precision machining of products made of cemented carbide, high temperature metal alloys, new energy materials, metal matrix composite materials, and nonferrous metal alloys. Outstanding outcome has been achieved in research, equipment development, production and sales.

The products and technologies from Aseeder, a well-known international brand, have been widely applied in the fields of oil & gas, chemical engineering, subsea, nuclear power, military and aerospace industries. Our market is strategically targeted at Fortune 500 companies. Seed has steadily evolved to be the leading export enterprise in China of wear-resistant cemented carbide products and the related high-precision machining techniques.

ASEEDER is dedicated to providing solutions for challenging conditions via our superior technologies of high-precision machining, additive manufacturing, and intelligence production, which have LED ASEEDER to become a premium global supplier and service provider in the field of cemented carbide products and new energy metallic materials.

Product List

-

-

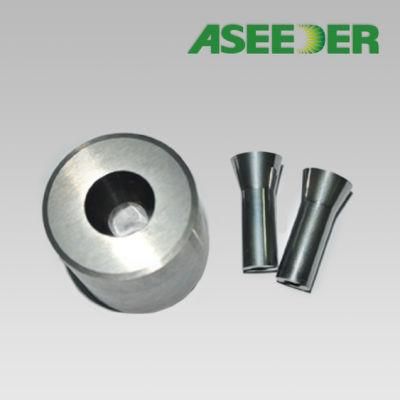

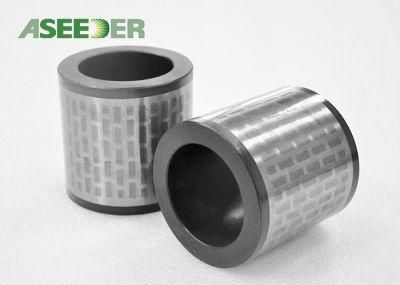

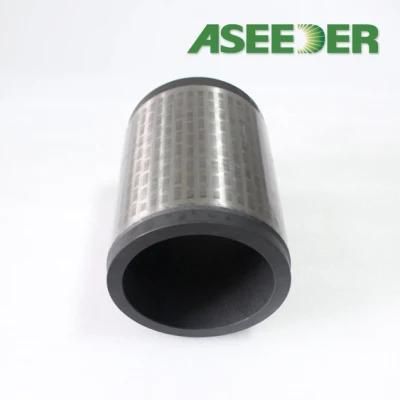

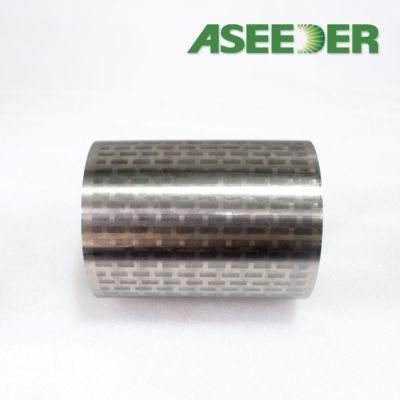

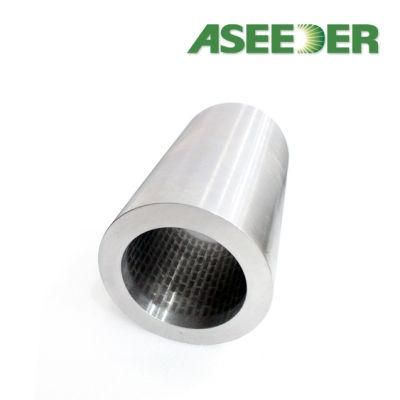

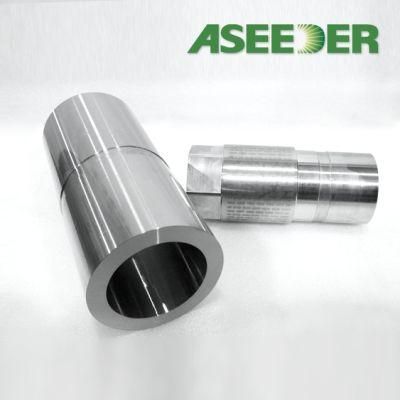

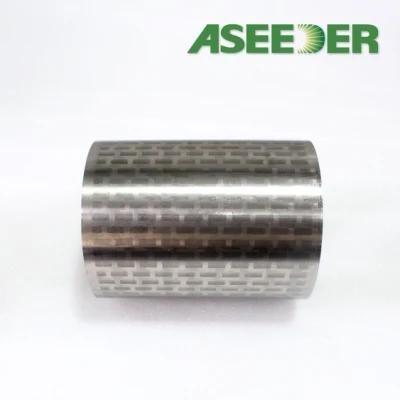

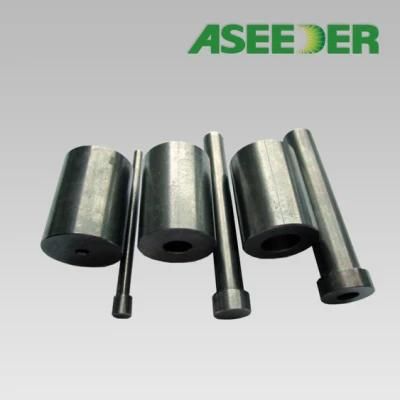

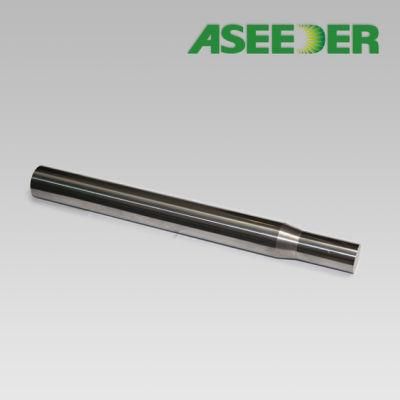

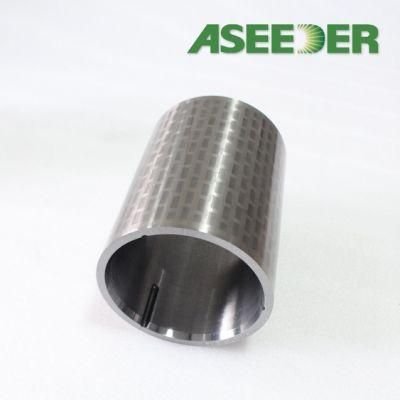

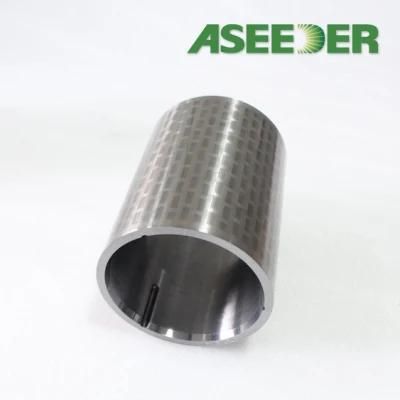

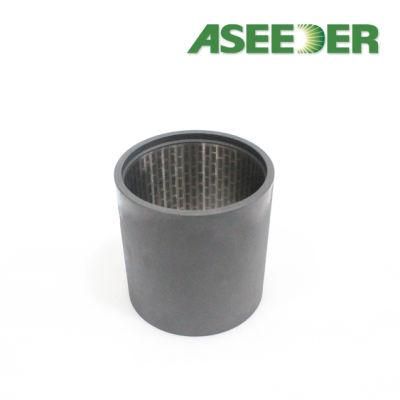

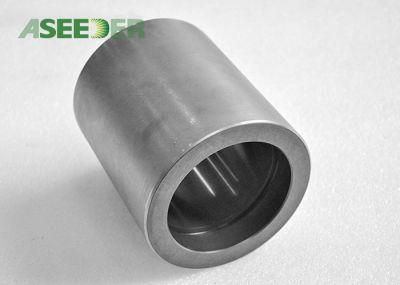

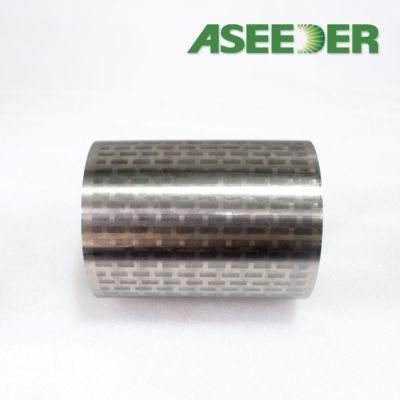

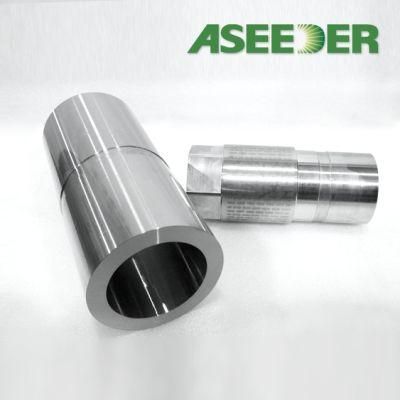

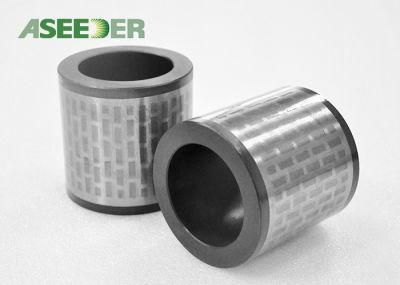

Top Grade Raw Material Tc Radial Bearing Customized for Downhole Motor

-

-

Three Plunger Homogenizer Wear and Corrosion Resistant Parts Carbide Valve Seat / Plunger

-

-

Cemented Tungsten Carbide Other Wear Parts for Oil and Gas Industy High Precision

-

-

Aseeder High Strength Wear Parts High Stability for Oil and Gas Industy

-

-

Most Hardest Shape Other Wear Parts for Oil and Gas Industy High Accuracy

-

-

Long Lasting Time Other Wear Parts for Oil and Gas Industy with Cemented Carbide Materials

-

-

No Standard Size Cemented Tungsten Carbide Wear Parts for Oil / Gas Industry

-

-

API Certificated High Quality Tungsten Carbide Spare Parts for Downhole Tools

-

-

Mwd & Lwd Tool Spare Parts Wear Parts Poppet with Custom Design

-

-

China OEM High Quality Tungsten Carbide Product

-

-

Tungsten Carbide Choke Valve Choke Bean High Pressure Design for Flow Control

-

-

Tungsten Carbide Choke Bean Prevent The Damages with Long Service Life

-

-

High Precision Choke Bean 1/64 - 134/64 Size for Ajustable Choke Valves

-

-

410ss Body Material Choke Stem and Seat Excellent Thermal Shock Resistance

-

-

Cameron Type H2 Big John Choke Bean Customizable Size Long Service Life

-

-

Good Impact Toughness Choke Bean Used Body Material 410ss with Tungsten Carbide

-

-

Tungsten Carbide Frac Plunger

-

-

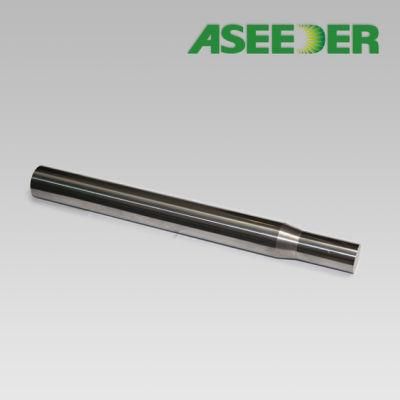

Corrosion Resistance and Wear Resistance Cemented Tungsten Carbide Plunger with OEM Service

-

-

Customized Nozzle Root Extension Extended Seat Used for PDC Drill Bits

-

-

Downhole Drilling Stabilizers Spare Parts with Customized Design

-

-

Abrasive Tc Plunger Tungsten Carbide Plunger for Booster Pump

-

-

Various Size Tungsten Carbide Plunger for Fracturing Pumps

-

-

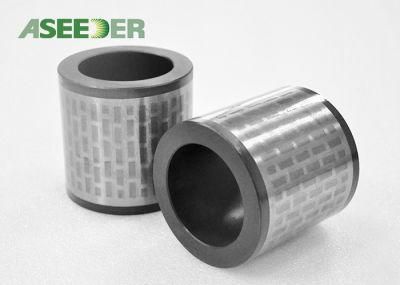

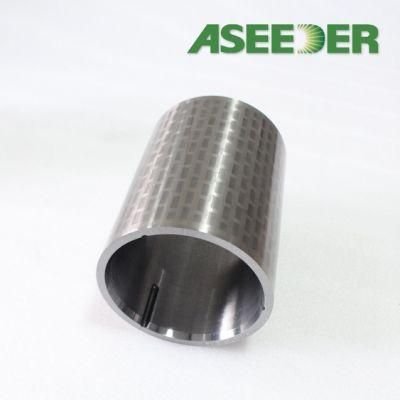

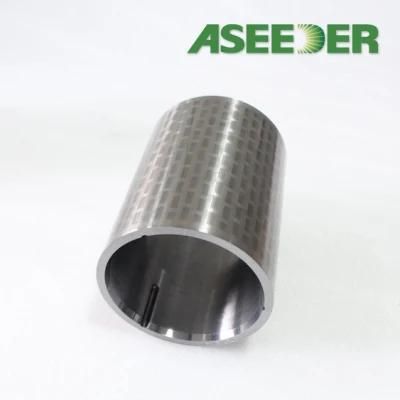

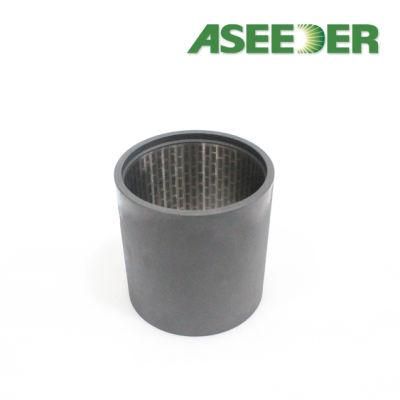

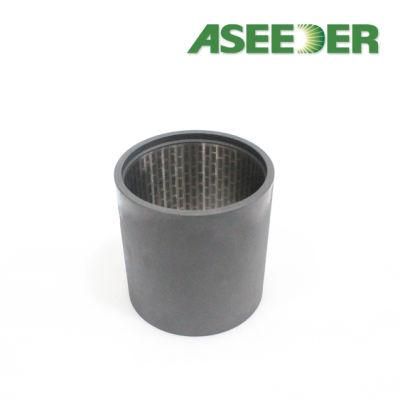

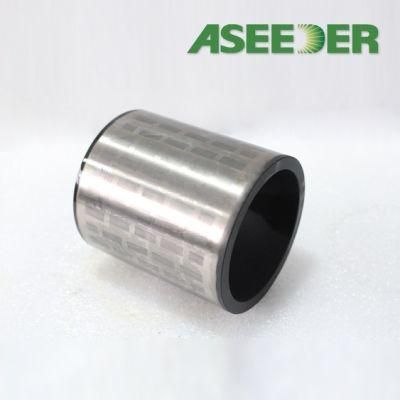

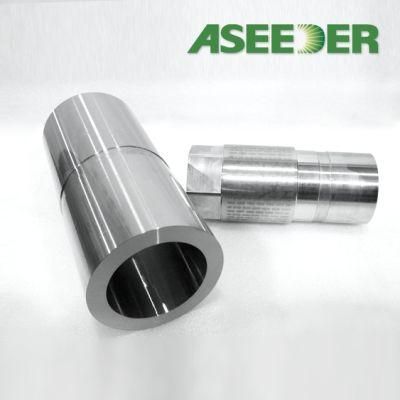

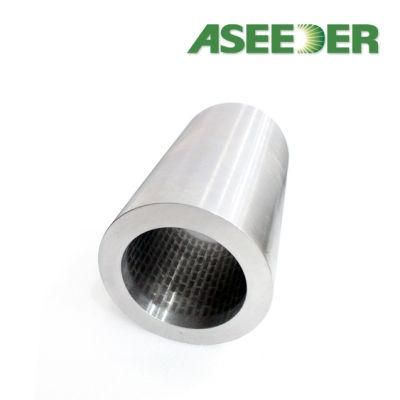

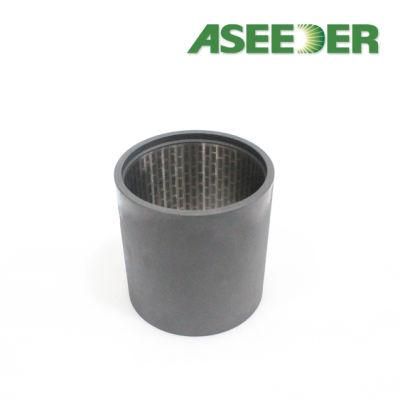

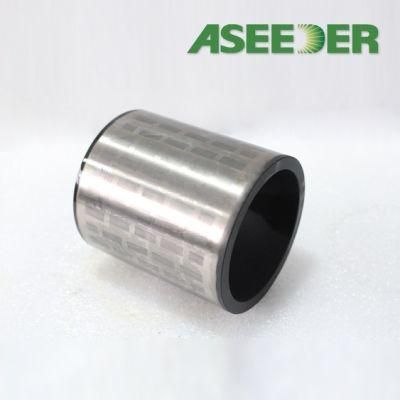

PDC Bushing /PDC Sleeve/ PDC Inserted Radial Bearing with OEM Service

-

-

Tungsten Carbide Plunger for Fuid End Accessories

-

-

Tungsten Carbide Plunger for Power End Accessories

-

-

Long Life Time API Approved Tungsten Carbide Tile Plain Shaft Bearing

-

-

Boron Carbide Venturi Nozzle/Sand Blasting Nozzle/Tungsten Carbide Nozzle/Drill Bit Nozzle/Mini Nozzle

-

-

Tungsten Carbide Parts for Frac Valves

-

-

Wear Resistance and Corrosion Resistance Pump Plunger for Piston Pump

-

-

Good Price Tunsten Carbide Pump Plunger Piston for Corrosion Resistance

-

-

Customized Large Fluted External Tc Bearing for Oil & Gas Field Application

-

-

Customized Wear Parts Impeller & Diffuser with Phosphating

-

-

Choke Bean Alloy 718 Nace with Tungsten Carbide Coating on Outside Diameter

-

-

Choke Part C/W Carbide Sliding Sleeve Tip Assy for Gear Actuator

-

-

High Standard Cemented Carbide Wear Parts High Temperature Resistance

-

-

Qualified Cemented Tungsten Carbide Components API Certificated Wear Parts

-

-

Cemented Tungsten Carbide Wear Parts Long Lifetime Asp9100 Certification

-

-

Customized Design Tungsten Carbide Wear Parts for High Pressure Conditions

-

-

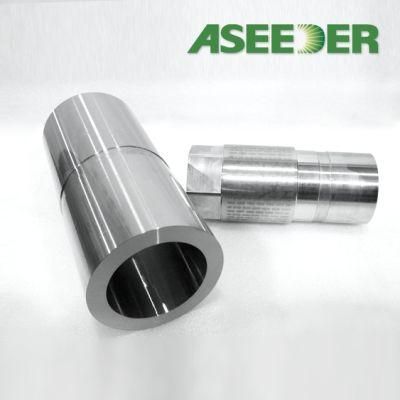

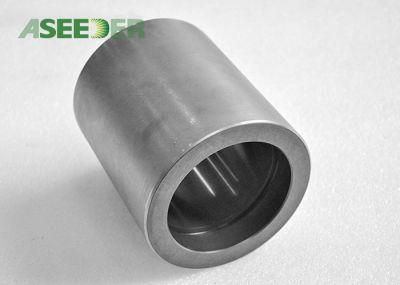

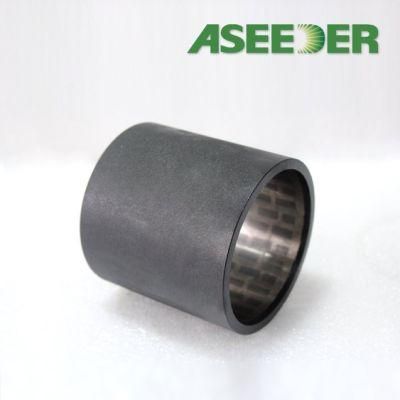

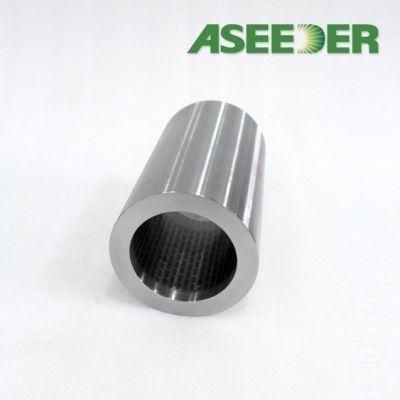

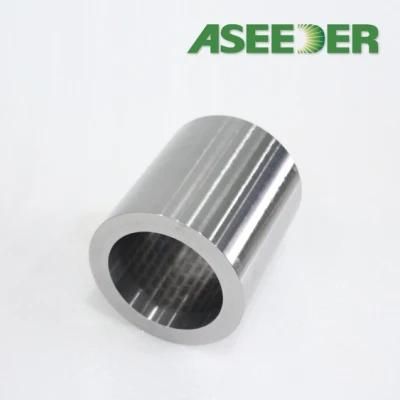

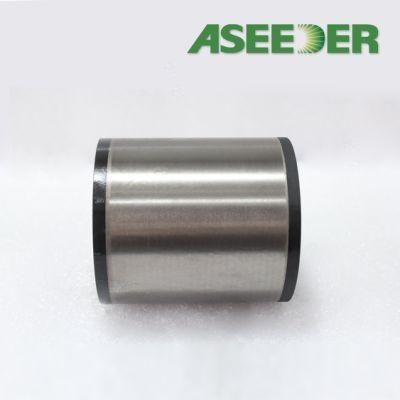

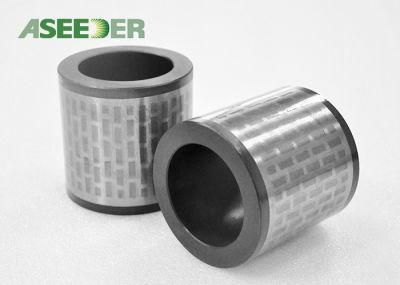

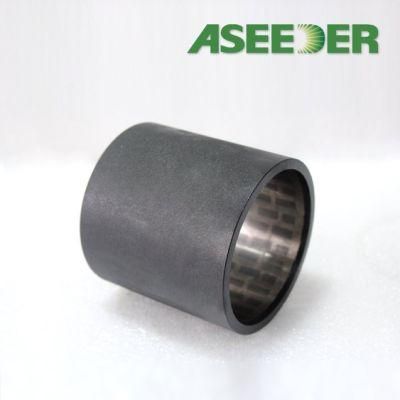

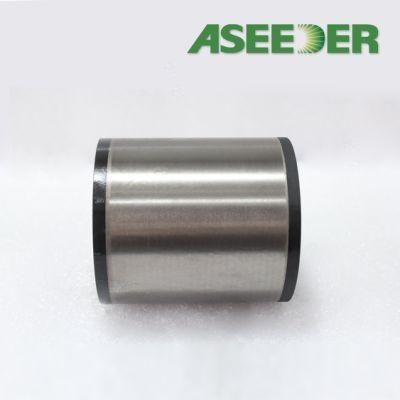

High Corrosion Resistance Insert Sleeve Bearing Bushing with Stable Chemical Property

-

-

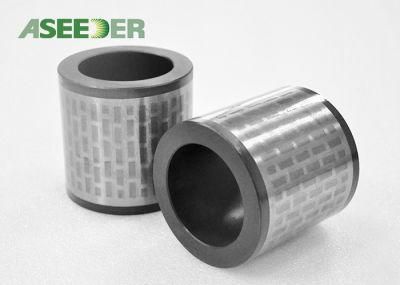

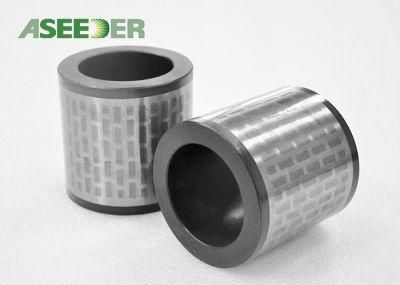

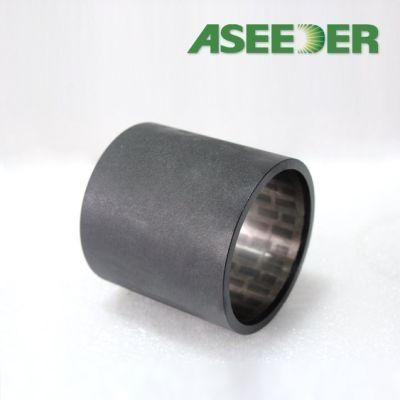

Hip Sintered Carbide Bushing Sleeve Bearing Widely Used in Petrochemical Industry

-

-

China Factory High Quality Mwd Components with OEM Service

-

-

China High Qualiuty Bent Housing for Downhole Motor

-

-

Special Shaped Mwd & Lwd Spare Parts with API Certification

-

-

API Certificated Wear Resistance Lwd Components for Oil & Gas Industry

-

-

Frac Pumps Spare Parts Tungsten Carbide Plunger

-

-

Wear and Corrosion Resistant Parts for Three Plunger Homogenizer

-

-

4" Tc Inserted Seat with Hardfacing

-

-

Yg6/Yg8/Yg10/Yg15 Tc Inserted Seat for Pumps

-

-

Customized Tc Inserted Seat / Tungsten Carbide Inserted Seat for Valves

-

-

Mwd Tool Customized Poppet with Tungsten Carbide

-

-

High Quality Custom Various Types Tungsten Carbide Tc Spray Dryer Nozzle/Spraying Nozzle/Sandblasting Blast Hoze Nozzle

-

-

Cemented Carbide Nozzle

-

-

Hot Sale DTH Drill Bit Use Thread Carbide Sand Blasting Nozzles for Mining or Water Well Project

-

-

Water Spray in Vortex, High Quality Spiral Jet, Silicon Carbide Sic Spray Nozzle

-

-

Boron Carbide/Silicon Carbide Sandblasting Venturi Nozzles with Jacket for Cleaning The Surface

-

-

DIY Customized Ruby Tipped Tungsten Carbide Nozzle for Coil Winding Machine

-

-

High Pressure Top Grade Spray Nozzle Flat Jet Nozzles Professional Factory High Pressure Tc Nozzle

-

-

Customized Manufacture Dispense Jet Tungsten Carbide Nozzle Orifice Diameter 0.025mm - 1.0mm

-

-

New Screw Type Tungsten Carbide Nozzle Oil Drill Bit Water Spray Nozzles

-

-

Tungsten Carbide Sandblast Nozzles

-

-

Competitive Yg10 Carbide Drills, PDC Drill Bit Special Nozzle, Tungsten Carbide Sandblast Nozzles

-

-

High Polished Yg6X Carbide Spray Nozzle 3D Printer Tungsten Carbide Nozzles

-

-

Tungsten Carbide Sdx Swirls Chambers with Different Type Spray Drying Nozzles

-

-

Custom Tungsten Carbide Nozzle

-

-

Customized Tungsten Carbide Nozzle Wear-Resistant Hard Alloy Nozzle Non-Standard Special-Shaped Tungsten Steel Fittings

-

-

Long Service Life Sic Silicon Carbide Boron Carbide Nozzle for Sand Blasting

-

-

Thread Boron Carbide Venturi B4c Nozzle 1-1/4′ ′ -11-1/2 (NPSM)

-

-

Tungsten Carbide for Sandblasting Nozzle Carbide 3D Carbide Water Jet Nozzle

-

-

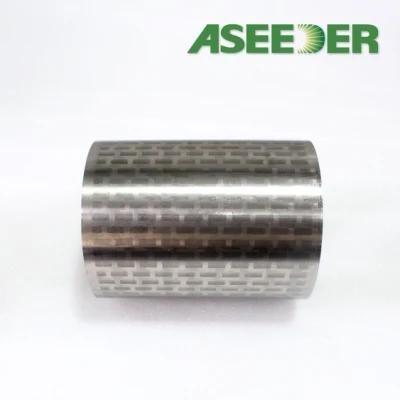

China High Quality Tile Tc Bearings Supplier Support OEM & Ode Service

-

-

Most Commonly Used Tile Tc Bearings for Mud Lubricated Drilling Tools

-

-

High Temperature Tungsten Carbide Choke Bean for Controlling Flow

-

-

Choke Bean Choke Stem with Sufficient Strength and Rigidity

-

-

High Hardness PDC Thrust Bearing, PDC Cutter Insert Bearing for Downhole Motor

-

-

Tungsten Carbide Radial Bearing and Thrust Bearing Drilling Mud Motor Use

-

-

High Hardness Cemented Carbide Thrust Radial Bearing for Oil and Gas Industry

-

-

High Strength PDC Thrust Bearing, PDC Cutter Insert Bearing for Downhole Motor

-

-

Aseeder PDC Cemented Carbide Thrust Radial Bearing for Oil / Gas Industry

-

-

High Tech Pta Radial Bearing Good Compactness with Enhanced Drilling Accuracy

-

-

AISI 4140 Mud Motor Radial Bearing, Tungsten Carbide Bearings Increased Bearing Life

-

-

Good Wear Resistant Plain Shaft Bearing Aseeder with Increased Bearing Life

-

-

Tungsten Carbide Mud Motor Radial Bearing 30 - 70HRC Hardness Hip Sintering

-

-

Professional Pta Plain Shaft Bearing with Excellent Performance for Mud Motor

-

-

Premium Drilling Motor Carbide Insert Bearing Zy06X Grade Anti Friction Bearing

-

-

Typical Tungsten Carbide Pta Radial Bearing Customized Design Long Service Life

-

-

Premium Quality Radial Thrust Bearing Hip Sintering for Drilling Mud Motor

-

-

Mud Motor Plain Shaft Bearing Size 54 to 286 Reduced Operational Costs

-

-

Tungsten Carbide Tc Cemented Carbide Thrust Radial Bearing Stable Chemical Property

-

-

Used for Pump in Oil / Gas Industry Tungsten Carbide Thrust Radial Bearing

-

-

OEM Customized Cemented Carbide Thrust Radial Bearing with Good Corrosion Resistance

-

-

Good Performance Tungsten Carbide Bearings High Durability in Mud Lubricated Drilling Tools

-

-

Tungsten Carbide Tile Plain Shaft Bearing Long Life Time API Approved

-

-

Professional Design Pta Plain Shaft Bearing with Excellent Performance for Mud Motor

-

-

Silver Color Pta Tc Bearing, Tile Tungsten Bearing for Drilling Mud Motor

-

-

High Standard Pta Radial Bearing with Excellent Wear Resistance for Downhole Motor

-

-

Tungsten Carbide Tile Plain Shaft Bearing OEM for Oil Drilling Mud Pump

-

-

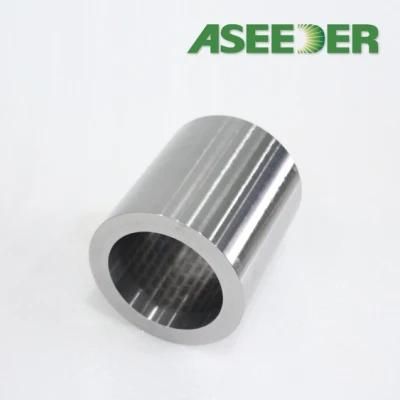

High Strength Carbide Bushing Sleeve Bearing ISO9001 for Oil and Gas Field

-

-

High Hardness PDC Radial Bearing for Oil for Gas Drilling Industry

-

-

Customized Size PDC Radial Bearing Durable for Turbo Drills, Mud Motors

-

-

Wear Resistant PDC Mud Motor Radial Bearing Radial Tungsten Carbide Bearings

-

-

As09529 PDC Cutter Insert Bearing PDC Radial Bearing with 1 Inch - 10 Inch Diameter

-

-

Top Grade Steel Grade PDC Radial Bearing Excellent Thermal Shock Resistance

-

-

Premium PDC Mud Motor Radial Bearing PDC Thrust Bearing for Oil Field

-

-

Polycrystalline Diamond PDC Cutter Insert Bearing with Ultra Fine Surface Treatment

-

-

API Standard PDC Radial Bearing PDC Cutter Insert Bearing for Turbo Drills

-

-

Aseeder Tile Tungsten Material ODM / OEM Design Tile Sliding Radial Bearing

-

-

Compact Size Mud Motor Radial Bearing Wear Resistance Outside Diameter 3/4 - 12

-

-

Drilling Tungsten Carbide Tile Sliding Radial Bearing with Increased Bearing Life

-

-

High Durability Tile Sliding Radial Bearing Hip Sintering for Drilling Mud Motor

-

-

Oil and Gas Industry Sliding Radial Bearing ODM & OEM with Long Life Time

-

-

Good Compression Custom Sliding Radial Bearing, Aseeder Sliding Radial Bearing Sleeve

-

-

Long Life Time Tile Sliding Radial Bearing with Unsurpassed Quality Standards

-

-

Tile Tungsten Material Tile Sliding Radial Bearing with Greater Drilling Accuracy

-

-

Great Drilling Accuracy Sliding Surface Radial Plain Bearing for Oil and Gas Industry

-

-

Wear Resistant Tile Sliding Radial Bearing for Mud Motor for Control Improvement

-

-

Small Size Radial Tc Bearing Tungsten Carbide Tile Bearing Increased Bearing Life

-

-

Good Wear Ability Custom Tc Radial Bearing Tungsten Carbide Bearings Wide Application

-

-

Highly Durable Tungsten Carbide Tc Radial Bearing Even Under Extreme Heat and Stress

-

-

Tile Tungsten Materials Tungsten Carbide Tc Radial Bearing Anti Friction Bearing

-

-

Aseeder Tungsten Carbide Tc Radial Bearing for Mud Motor in Oil and Gas Indutry

-

-

Improved Mud Motor Performance Tungsten Carbide Tc Radial Bearing ISO Compliant

-

-

Less Drilling Time Tungsten Carbide Tc Radial Bearing with Permitting Sharper Turns

-

-

Silver Color Mud Motor Radial Bearing Aseeder with Enhanced Drilling Accuracy

-

-

Oil Industry Tungsten Carbide Tc Radial Bearing 30 - 70HRC Hardness Aseeder

-

-

High Precision Radial Tc Bearing, Tungsten Carbide Tile Bearing for Mud Motor

-

-

Hip Sintering Tungsten Carbide Tc Radial Bearing to Improve Mud Motor Performance

-

-

Good Compactness Custom Wear Resisting Long Lifetime Tungsten Carbide Tc Radial Bearing

-

-

ISO Approved Tungsten Carbide Tc Radial Bearing for Increasing Bearing Life

-

-

Corrosion Resistance Hardfacing Pump Plunger with Long Service Life

-

-

Wear Resistance Cemented Tungsten Carbide Plunger for High-Pressure Pump

-

-

Customzied Tunsten Carbide Pump Plunger for Corrosion Resistance

-

-

Wear Resistance Hardfaced Pump Plunger with Material 38crmoai

-

-

Customized Wear Resistance Plunger Piston with Material 40cr

-

-

Nozzle 5500 Castle Used for PDC Drill Bits

-

-

PDC Drill Bits Nozzles with OEM Service

-

-

TCP Tile Radial Bearings for Drilling Mud Motors. Different Sizes

-

-

TCP Tile Carbide Radial Bearing for Drilling Mud Motors

-

-

Wear Resistance Surface Choke Made by 410 W/ Tc Insert

-

-

50/ 55/65 Series / 65 Series PDC Nozzles with Long Life Time

-

-

Cemented Tungsten Carbide Sliding Sleeve for Choke Part

-

-

China Manufacture Oil Spray Tungsten Cemented Carbide Nozzle

-

-

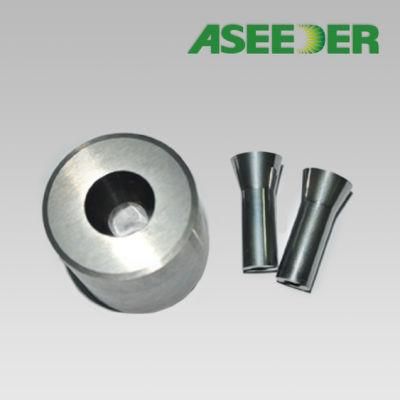

Tungsten Carbide Plug Tip in Conjunction with Solid Tungsten Carbide Cage

-

-

Wear Resistant Radial Tungsten Carbide Tc Bearing

-

-

Custom Made Cemented Carbide Wear Parts / Strong Head Thread Nozzle

-

-

Custom Seat Assembly with Nickel Binder Insert

-

-

High Quality Trim Set Tungsten Carbide Matche Plug

-

-

API Certificated Tungsten Carbide Nozzle Jet for Wear Resistance

-

-

Wear Parts Series 75 Carbide Nozzle with High Quality

-

-

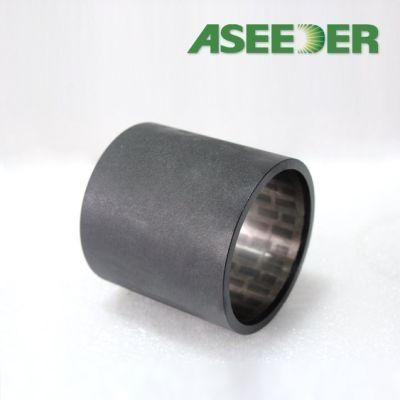

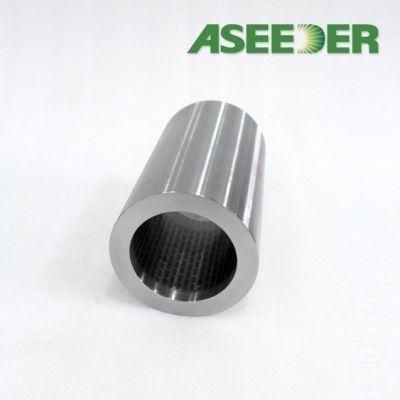

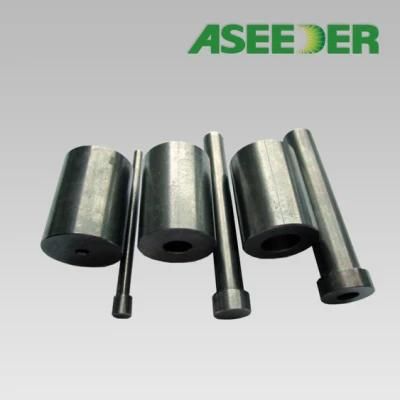

Tungsten Carbide Cylinder Bushing Sleeve

-

-

Petrochemical Industries Carbide Bushing Sleeve Bearing with Nitriding Coated

-

-

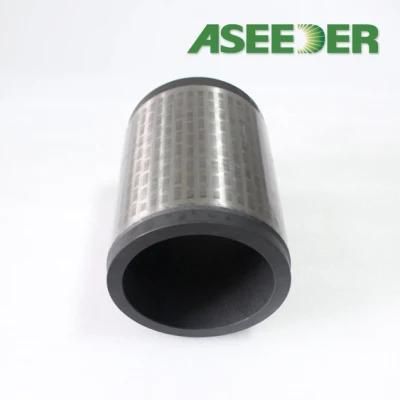

Cemented Tungsten Carbide Sleeves and Bushings for Bearing

-

-

Machinery Accessories Tungsten Carbide Bearing Bushing

-

-

Wear Resistant Components Tungsten Carbide Sand Catcher

-

-

Tungsten Carbide Valve Part Flow Sleeve with Unregular Holes

-

-

Wear-Resistance Tungsten Carbide Seat for Valves Application

-

-

Special Shaped Bearing Tungsten Cemented Carbide Bushing

-

-

Customized Throttle Valve Wear Parts for World Fortune 500 Companies

-

-

Wear Resistance Carbide Bushing Sleeve Bearing with 100% Raw Material

-

-

17-4pH PDC Thrust Bearing for Motor Stator

-

-

Pure Tungsten Water Spray Nozzle with High Cutting Speed

-

-

Carbide Custom-Designed Threaded Nozzles Are Manufactured

-

-

Good Quality Roctec 500 Tungsten Carbide Water Jet Cutting Nozzles

-

-

Tungsten Carbide/ Carbide Shot Blast Nozzle

-

-

Boron Carbide Sandblasting Nozzles, Blasting Machine Nozzles

-

-

High Density Sand Blasting Gun Boron Carbide Blasting Nozzle 20mm*80mm

-

-

35*15*3mm Boron Carbide B4c Sandblasting Nozzle

-

-

China Carbide Manufacturer Supply Tungsten Carbide Sandblast Water Nozzle

-

-

Tungsten Carbide Sandblast Nozzle in High Wear-Resistance

-

-

China Factory Factory Direct Tungsten Carbide Nozzle Seal Ring/Bush/Sleeve/Tube/Nozzle

-

-

Tungsten Carbide Industry Abrasive Sand Blasting Nozzle Oil Nozzle

-

-

Cross Groove Thread Nozzle Tungsten Carbide Nozzle

-

-

Water Well Tricone Drill Bit Tungsten Carbide Nozzles

-

-

Good Price Roctec 500 Tungsten Carbide Water Jet Cutting Nozzles

-

-

Customized Boron Carbide or Tungsten Carbide Nozzles

-

-

High Precision Manufacturing Special Shaped Tungsten Carbide Nozzle

-

-

Sand Blasting Tungsten Carbide Nozzle Blank

-

-

High Wear Resistant Tungsten Carbide Venturi Sandblasting Nozzle for Sale

-

-

Wholesale Tungsten Cemented Carbide Jet Nozzle for Aluminium Industry

-

-

Hot Sales Cemented Tungsten Carbide Sandblast Nozzles From China

-

-

Factory Supply Tungsten Carbide Oil Drill Bit Nozzle

-

-

Wear Resistant Solid Carbide Hard Metal Blast Nozzle

-

-

Professional Manufacturer Supply Tungsten Carbide Sandblast Water Nozzle

-

-

K10 Tungsten Carbide Bit Nozzle for Oil Field Tool

-

-

Tungsten Carbide PDC Drill Bit Nozzles for Drilling

-

-

High Quality Factory Directly Supply Tungsten Carbide Nozzle Customized Size

-

-

Hot Selling Tungsten Carbide 3D Printer Nozzle

-

-

Carbide 3D Printer Carbide Bit Tungsten Carbide Sandblasting Nozzle

-

-

Manufacturer Provide Water Jet Tungsten Carbide Spray Nozzle for Sandblasting

-

-

Cemented Tungsten Carbide Nozzle for All Kinds of Industry Application

-

-

Seeder Customized Corrosion Resistance Tungsten Carbide Nozzle for Water Spray

-

-

High Hardness Tungsten Carbide Water Jet Cutter Carbide Nozzle

-

-

OEM & ODM Tungsten Carbide Blasting Nozzle

-

-

Wholesale Sandblasting Tungsten Carbide Nozzle

-

-

High Quality Tungsten Carbide Abrasive Waterjet Nozzle

-

-

Tungsten Carbide Nozzle with High Hardness and Resistance

-

-

Hard Alloy Main Carbide Ultra Abrasion Resistant Nozzle

-

-

Super Hardness Boron Carbide B4c Ceramic Nozzle

-

-

Automatic Dustless Blasting with Boron Carbide Nozzle for Spare Parts

-

-

Quality Sandblasting Spray Sandblast Gun Boron Carbide Nozzles

-

-

Gw Carbide - Tungsten Carbide Nozzles for Spraying Nozzle

-

-

Quality Sandblasting Machine Spray Gun Boron Carbide Nozzles