Tungsten Carbide Cylinder Bushing Sleeve

SEED TECHNOLOGlES CORP., LTD.- Manufacturing Process:Hip Sintering

- Surface Treatment:Polish

- Operation Pressure:Vacuum

- Material:Tungsten Carbide

- Features:Wear-Resisting Long Life

- Feature:Anti Corrosion

Base Info

- Application:Oil & Gas Industry,Pump etc

- Working Temperature:>2000 Degree

- Service:Customized ODM OEM

- Advantage:High Rigidity & Durable

- Size:Customized

- Transport Package:Standard Package , Customize Packing

- Specification:as per specific requirement

- Trademark:Aseeder

- Origin:China

- HS Code:84819000

- Production Capacity:10000 PCS Per Month

Description

(Wt %)

(g/cm3)

(≥N/mm²)

Features:

1. Use 100% tungsten carbide raw material

2. Stable chemical properties

3. Excellent performance and good wear / corrosion resistance

4. HIP sintering, good compactness

5. Blanks, high machining accuracy / precision

6. OEM customized sizes available

7. Factory's offer

8. Strict products quality inspection

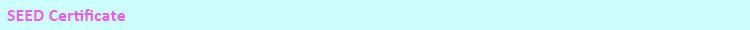

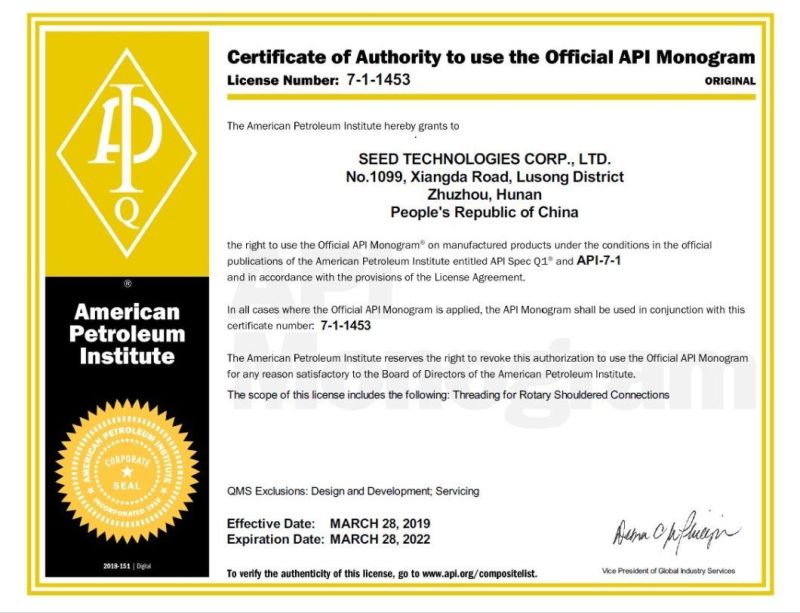

Seed Technologies Corp., LTD., located in Zhuzhou (China), is a high-tech developer, manufacturer, and distributor of superior wear resistant parts, tool assembly and equipment for Oil and gas, Aerospace, Valve and Pumps industry.

Aseeder Corporation was invested by Seed as a Houston based company dedicated for sales and customer support in north America market.

The products and technologies from Seed (Aseeder) have been widely applied in the fields of oil & gas, chemical engineering, subsea, nuclear power and aerospace industries. Mainly used in harsh operating conditions include severe abrasion, erosion, corrosion, high temperature, high pressure and strong impact.

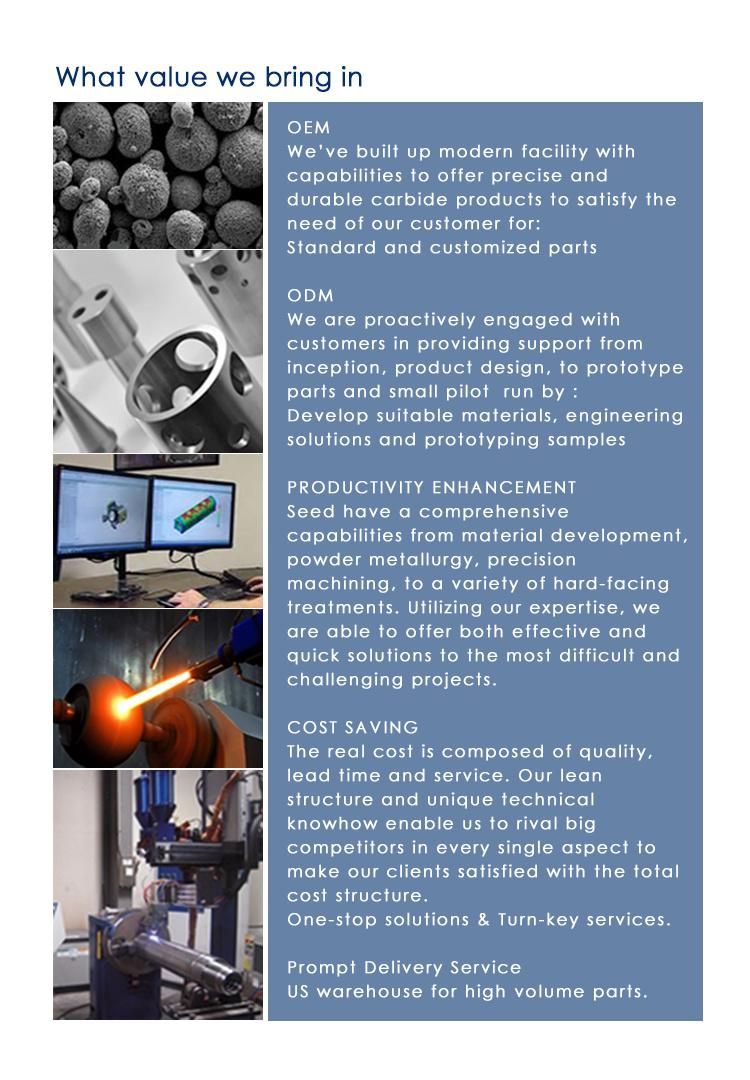

1. Advanced Machining and Test Equipments:

2. Outstanding ability to meet all of customer's requirements:

3. High Precision Product machining Lines:

· Wear resistant carbide components via powder metallurgy technique

· Hardfacing (oxy-acetylene spray, PTA, HVOF, etc.) and surface enhancement (phosphating, boronizing, etc.)

· High-precision machining of metals (S.Steel, carbon steel, Inconel 718, etc.)

· Additive manufacture

4. Abundant experience accumulation in serving Fortune 500 companies in Oil & Gas Industry:

a, Flexible payment term

b, Expedite communications

c, Quick and Professional Response