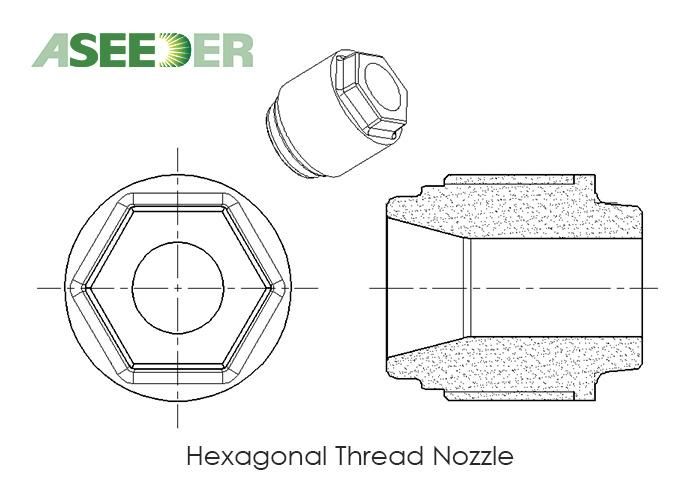

Customized Boron Carbide or Tungsten Carbide Nozzles

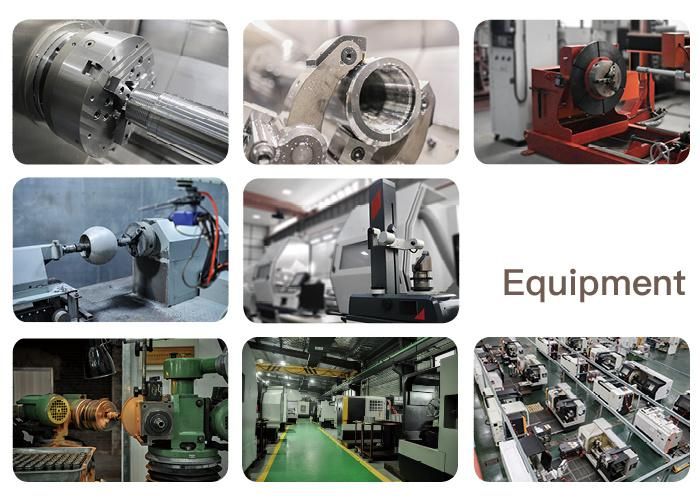

SEED TECHNOLOGlES CORP., LTD.- Manufacturing Process:Hip Sintering

- Surface Treatment:Polish

- Operation Pressure:Vacuum

- Material:Tungsten Carbide

- Features:Wear-Resisting Long Life

- Feature:Anti Corrosion

Base Info

- Model NO.:Seeder _0489

- Application:Oil & Gas Industry,Pump etc

- Service:Customize ODM OEM

- Advantage:High Rigidity & Durable

- Size:Customized

- Grade:Zy11-C

- Density:14.33-14.53

- Grain Size:1.2-2.0

- Hardness:88.6-90.2 Hra

- Transport Package:Standard Package , Customize Packing

- Trademark:Aseeder

- Origin:China

- HS Code:84819010

- Production Capacity:5000 PCS Per Month

Description

(Wt %)

(g/cm3)

(≥N/mm²)

Major Product Lines

· Wear resistant carbide components via powder metallurgy technique

· Hardfacing (oxy-acetylene spray, PTA, HVOF, etc.) and surface enhancement (phosphating, boronizing, etc.)

· High-precision machining of metals (S.Steel, carbon steel, Inconel 718, etc.)

· Additive manufacture