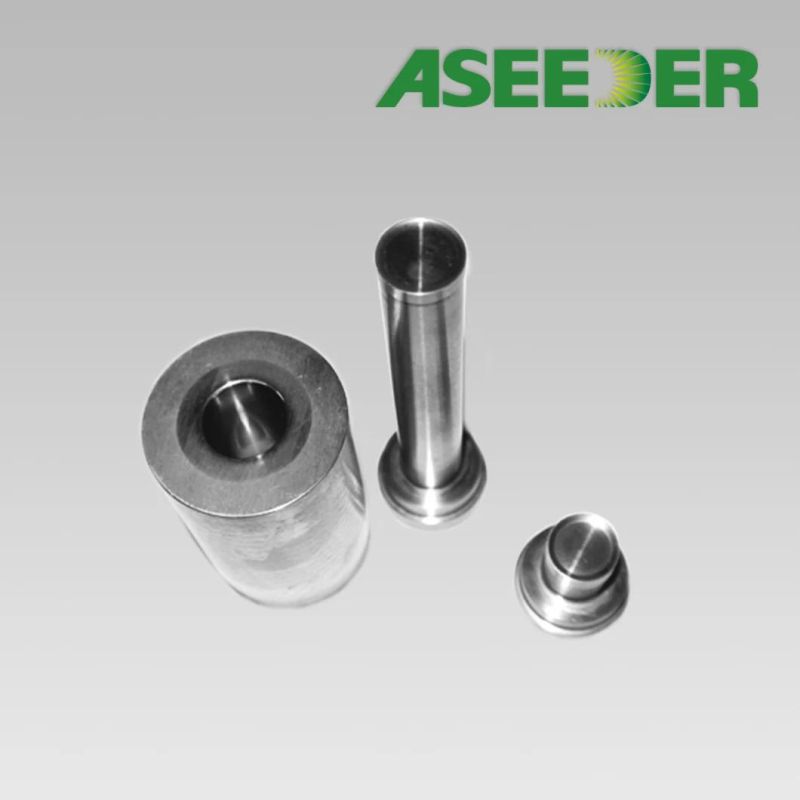

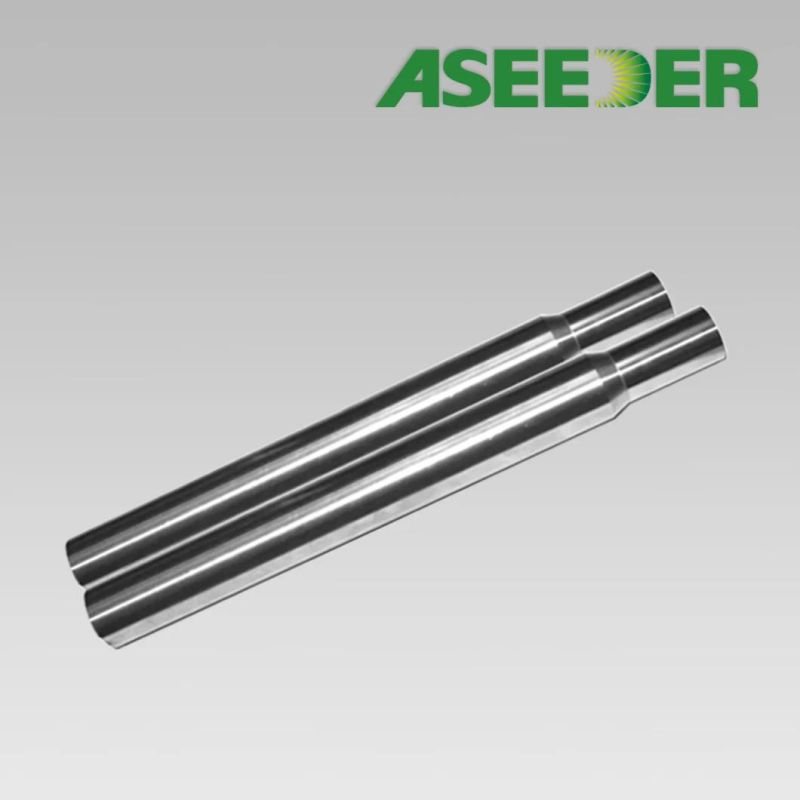

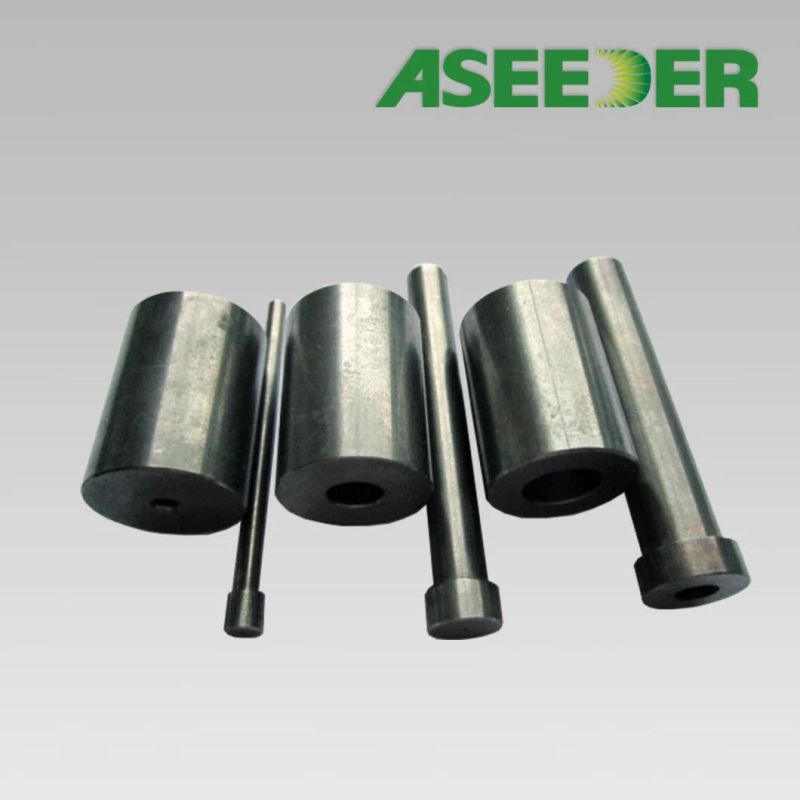

Wear and Corrosion Resistant Parts for Three Plunger Homogenizer

SEED TECHNOLOGlES CORP., LTD.- Manufacturing Process:Per Customer Requirement

- Surface Treatment:Per Customer Requirement

- Operation Pressure:Per Customer Requirement

- Material:Tungsten Carbide

- Transport Package:Standard

- Specification:per customer requirement

Base Info

- Model NO.:Seeder 7215

- Trademark:Aseeder

- Origin:China

- HS Code:84819000

- Production Capacity:10000 PCS Per Month

Description

Detailed Photos Certifications Our Advantages · Wear resistant carbide components via powder metallurgy technique · Hardfacing (oxy-acetylene spray, PTA, HVOF, etc.) and surface enhancement (phosphating, boronizing, etc.) · High-precision machining of metals (S.Steel, carbon steel, Inconel 718, etc.) · Additive manufacture

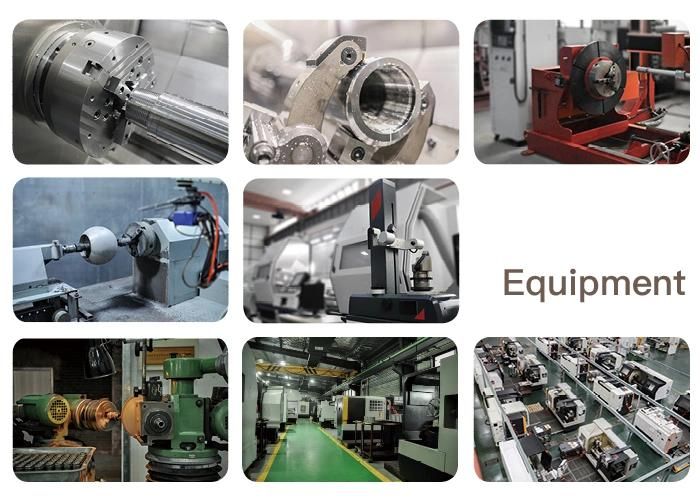

1. Advanced Machining and Test Equipments:

2. Outstanding ability to meet all of customer's requirements:

3. High Precision Product machining Lines:

4. Abundant experience accumulation in serving TOP 10 companies in Oil & Gas Industry:

a, Flexible payment term

b, Expedite communications

c, Quick and Professional Response