Choke Bean Alloy 718 Nace with Tungsten Carbide Coating on Outside Diameter

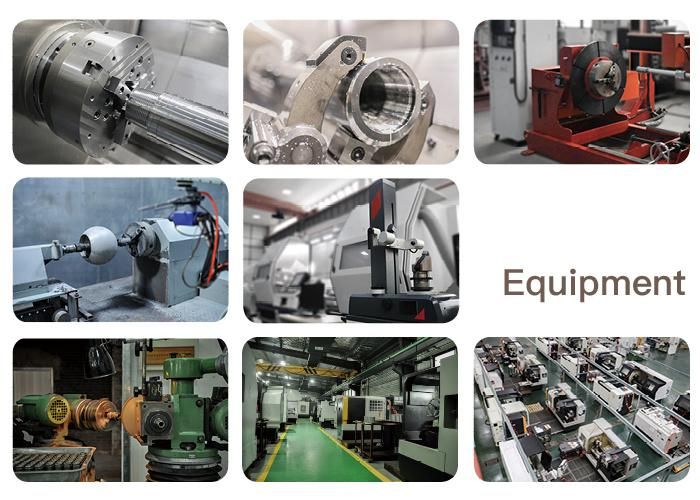

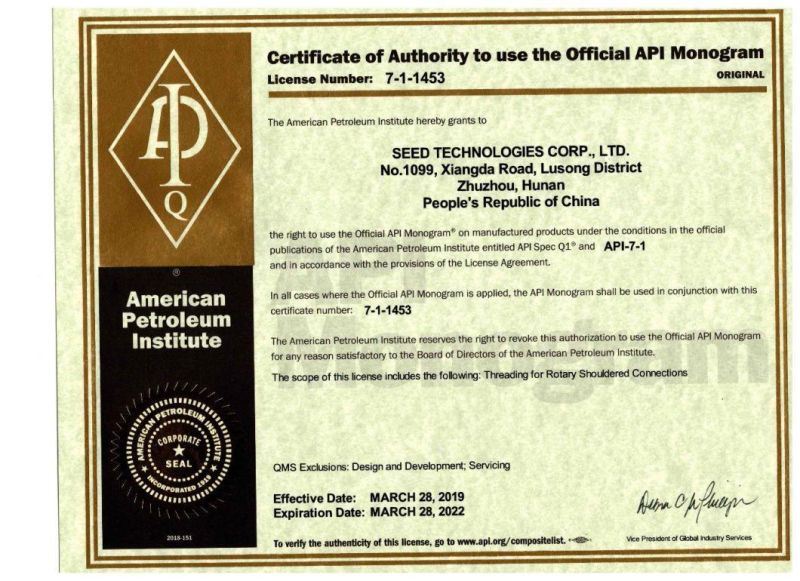

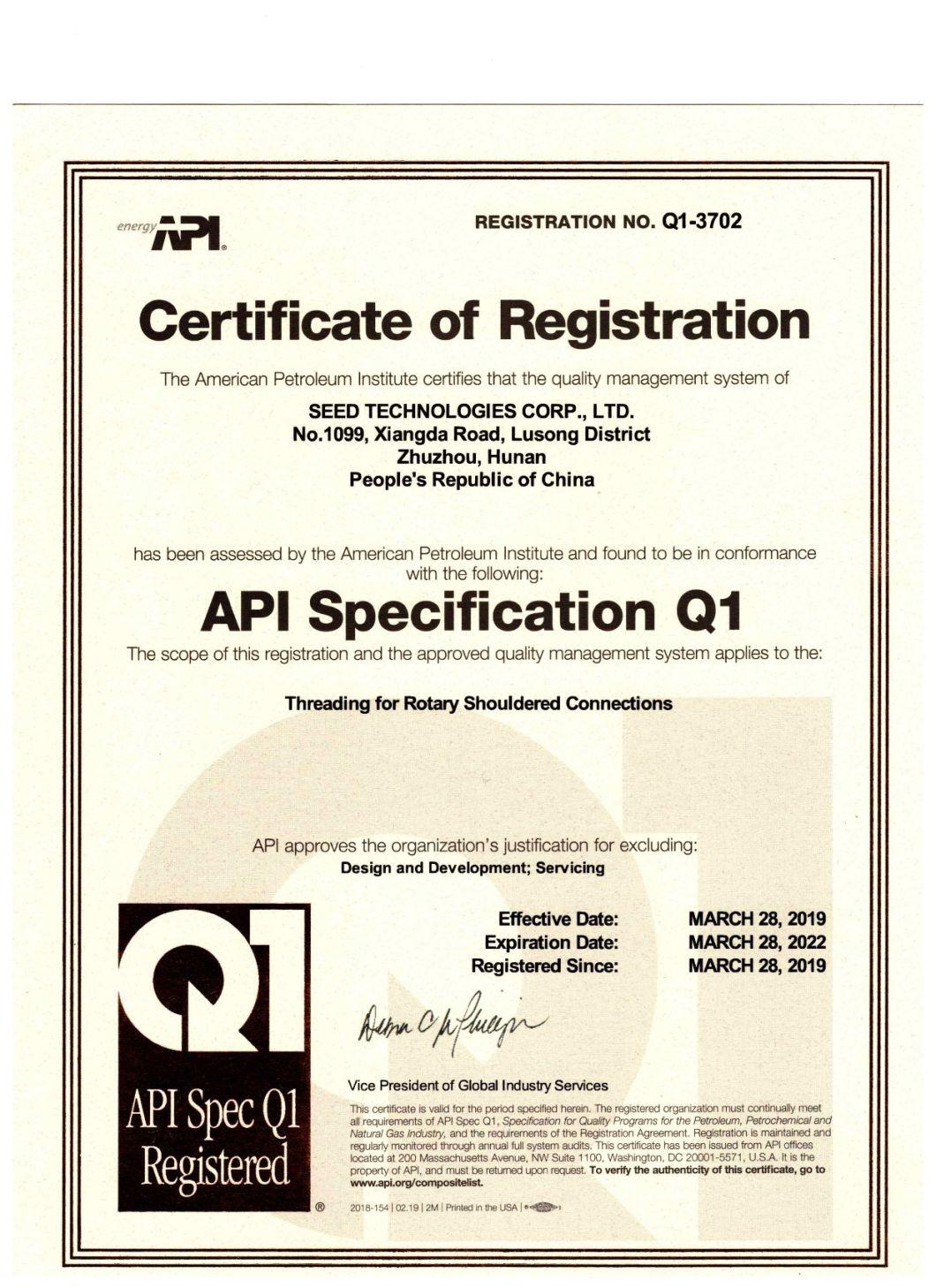

SEED TECHNOLOGlES CORP., LTD.- Manufacturing Process:Hip Sintering

- Surface Treatment:Polish

- Operation Pressure:Vacuum

- Material:Tungsten Carbide

- Features:Wear-Resisting Long Life

- Feature:Anti Corrosion

Base Info

- Application:Oil & Gas Industry,Pump etc

- Working Temperature:in Excess of 2000° F (1093° C)

- Service:Customize ODM OEM

- Advantage:High Rigidity & Durable

- Size:Customized

- Transport Package:Standard Package , Customize Packing

- Specification:Tungsen carbide

- Trademark:Aseeder

- Origin:China

- HS Code:84819010

- Production Capacity:10000 PCS Per Month

Description

(Wt %)

(g/cm3)

(≥N/mm²)

Features:

1. Use 100% tungsten carbide raw material

2. Stable chemical properties

3. Excellent performance and good wear / corrosion resistance

4. HIP sintering, good compactness

5. Blanks, high machining accuracy / precision

6. OEM customized sizes available

7. Factory's offer

8. Strict products quality inspection