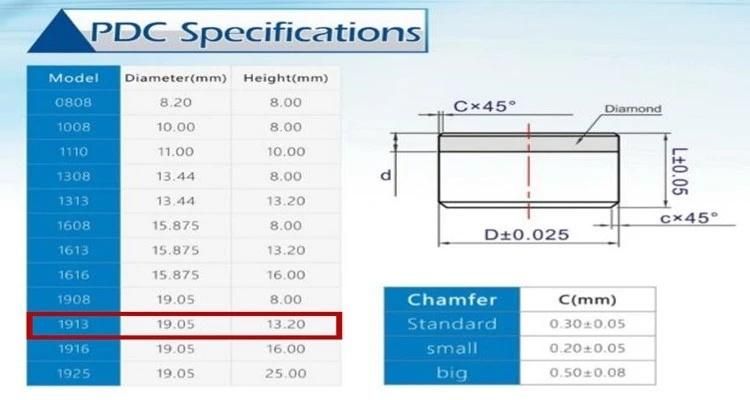

PDC Cutting Insert /Drilling PDC Cutters/PDC Cutter Insert 1913

Zhuzhou Up Cemented Carbide Co., Ltd.- Manufacturing Process:Stamping

- Surface Treatment:Polishing

- Operation Pressure:Atmospheric Pressure

- Material:Tungsten Carbide

- Diameter:19.05mm

- Length:13.2mm

Base Info

- Model NO.:1913

- Transport Package:25kg. Carton

- Specification:UG1913

- Trademark:ZZUP

- Origin:Zhuzhou, Hunan, China

- HS Code:820900100

- Production Capacity:10000000PCS,Month

Description

Basic Info.

Model NO. 1913 Transport Package 25kg. Carton Specification UG1913 Trademark ZZUP Origin Zhuzhou, Hunan, China HS Code 820900100 Production Capacity 10000000PCS/MonthProduct Description

PDC Cutting Insert /Drilling PDC Cutters/PDC Cutter Insert 1913PDC Cutting Insert /Drilling PDC Cutters/PDC Cutter Insert 1913c

Specificationspdc cutting insert /Drilling PDC Cutters/PDC cutter insert 1925

1.A PDC consists of a polycrystalline diamond layer and a cemented carbide substrate. It is made by sintering fine diamond powder and cemented carbide substrate together at a high atmospheric pressure and temperature (about 60,000atms and 1,400-1,500ºC). It is suitable for drill bits (PDC drill bits) working on various strata. Due to the complete D-D bondings among the diamond grains at the polycrystalline diamond layer, the diamond layer has high strength, hardness, and wear resistance and also shows excellent self-sharpening performance.

2. In its operation, a PDC drill bit crushes rocks by cutting and is more effective than a roller cone bit crushing rocks or an impregnated diamond bit ploughing and grinding rocks. The polycrystalline diamond layer and the cemented carbide substrate are combined in a tooth structure, thus consolidating the two layers and ensuring better impact resistance of the drill bit.

products series

Packing details

Shipping ways

Production process

Contact details

Miss.ivy yang

websit: http://upcarbide.en.made-in-china.com

http://upcarbide.en.made-in-china.com