Sand Control Sucker Rod Pump Sand Prevention Pump Plunger Pump

Puyang Chensheng Petroleum Technology Co., Ltd.- After-sales Service:1year

- Warranty:1year

- Manufacturing Process:Forging

- Surface Treatment:Sand Blast

- Operation Pressure:Atmospheric Pressure

- Material:Stainless Steel

Base Info

- Transport Package:Bulk

- Origin:Puyang Henan

Description

Basic Info.

Transport Package Bulk Origin Puyang HenanProduct Description

1.Ultra-deep Low Leakage Sucker Rod Pump

Product introduction: it is suitable for the middle and later stage of oil field exploitation. The pressure difference of pump barrel is zero in the working process, which greatly improves the working environment of oil pump and reduces the actual leakage.It has obtained the national patent.

Structure and Principle:

The pump is equipped with a bearing outer tube on the basis of the ordinary whole pump. The bottom end of the pump barrel is fixed on the outer tube and the upper end is suspended.When the pump is working, the annular space between the pump barrel and the outer pipe will be filled with oil, and the internal and external pressure difference is balance. greatly improves the working environment of the pump barrel.

| Model | Diameter mm | stroke m | Plunger length m | Connection tube OD mm | pump constant m/d | connection suck rod Dia mm |

| 25-125TH | ∮31.75 | 0.6~9.0 | 1.2 | ∮73.0 | 1.140 | ∮19 |

| 25-150TH | ∮38.10 | 0.6~9.0 | 1.2 | ∮73.0 | 1.642 | ∮19 |

| 25-175TH | ∮44.45 | 0.6~9.0 | 1.2 | ∮73.0 | 2.235 | ∮19 |

| 25-200TH | ∮50.8 | 0.6~9.0 | 1.2 | ∮73.0 | 2.965 | ∮19 |

| 25-225TH | ∮57.15 | 0.6~9.0 | 1.2 | ∮73.0 | 3.691 | ∮19 |

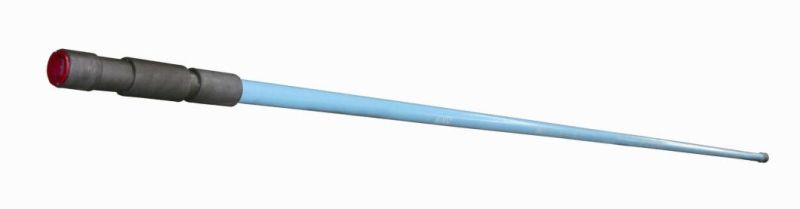

2. Sand Control Sucker Rod Pump

Well sand is often encountered in the oilfield production process, because crude oil seepage flow is in the mud pore environment, sand is inevitable, especially with the continuous development of the oilfield, the rise of water content and the surge of well sand more serious, using conventional pump pumping sand card, sand grinding phenomenon, make the pumping pump premature failure, resulting in well production and production.Industry, make the pumping pump premature failure, resulting in well production, frequent operation, increased production costs.Long plunger sand prevention pump has the advantages of sand prevention card, sand prevention grinding, sand prevention burial and long life, which greatly extends the cycle of inspection pump.

Well sand is often encountered in the oilfield production process, because crude oil seepage flow is in the mud pore environment, sand is inevitable, especially with the continuous development of the oilfield, the rise of water content and the surge of well sand more serious, using conventional pump pumping sand card, sand grinding phenomenon, make the pumping pump premature failure, resulting in well production and production.Industry, make the pumping pump premature failure, resulting in well production, frequent operation, increased production costs.Long plunger sand prevention pump has the advantages of sand prevention card, sand prevention grinding, sand prevention burial and long life, which greatly extends the cycle of inspection pump.Structure and working principle:

The sand prevention pump adopts long plunger, short pump cylinder and ring empty sand sink structure, It is mainly composed of long plunger, short pump cylinder, sand sink external cylinder, double joint and sand scraping device.

In the course of work, regardless of the plunger in any position, there is always a section of the plunger exposed above the pump tube.At the same time, the sand scraping device plays the role of sand scraping and sand division to prevent sediment sinking from entering the gap between the plunger and the pump cylinder. The sand particles can only sink into the annular air of the pump cylinder and the outer pipe to reduce the wear between the pump cylinder and the plunger and prolong the service life of the pump.

| Model | Diameter mm | stroke m | Plunger length m | Connection tube OD mm | pump constant m/d | connection suck rod Dia mm |

| 25-125TH | ∮31.75 | 0.6~9.0 | 6.6 | ∮73.0 | 1.140 | ∮19 |

| 25-150TH | ∮38.10 | 0.6~9.0 | 6.6 | ∮73.0 | 1.642 | ∮19 |

| 25-175TH | ∮44.45 | 0.6~9.0 | 6.6 | ∮73.0 | 2.235 | ∮19 |

| 25-225TH | ∮57.15 | 0.6~9.0 | 6.6 | ∮73.0 | 3.691 | ∮19 |

| 30-250TH | ∮63.50 | 0.6~9.0 | 6.6 | ∮88.9 | 4.560 | ∮22 |

| 30-275TH | ∮69.85 | 0.6~9.0 | 6.6 | ∮88.9 | 5.518 | ∮22 |

3.Operation Sucker Rod Pump with Pressure

Structure principle

The pump is to add the pressure operation blowout device on the basis of the general pump. The pressure operation blowout device is placed at the lower end of the general pump. In the process of pump dropping, the seal sleeve section seal with the fixed seat joint.Preventing the oil and gas from entering the pump pipe as blowout prevention and ensures the safe operation.When the operation pump with pressure can be down to the design depth, the pipe column of the pump is tested according to the design requirements, and the pressure is 6-8Mpa. The pin is cut off, and the sealing mandrel is ejected by the inertia force to the sealing mandrel, which falls into the tubing connecting the lower end of the pump.

| Model | Diameter mm | Stroke m | Plunger length m | Connection tube OD mm |

| 25-125TH | 31.75 | 0.6~9.0 | 1.2 | 73.0(2 7/8 TBG) |

| 25-150TH | 38.10 | 0.6~9.0 | 1.2 | 73.0(2 7/8 TBG) |

| 25-175TH | 44.45 | 0.6~9.0 | 1.2 | 73.0(2 7/8 TBG) |

| 25-200TH | 50.8 | 0.6~9.0 | 1.2 | 73.0(2 7/8 TBG) |

| 25-225TH | 57.15 | 0.6~9.0 | 1.2 | 73.0(2 7/8 TBG) |

| 30-275TH | 69.85 | 0.6~9.0 | 1.2 | 88.9(3 1/2 TBG) |

4.Anticorrosive Wearing Sucker Rod Pump

Product profile

Anti-corrosion abrasion pumping pump is a pumping pump manufactured by surface corrosion treatment according to the condition of oil well liquid corrosion medium. The pumping pump with intensive treatment can effectively prevent the corrosion medium such as H,S,CO,O2, saline in the general oil well and the corrosion or abrasive oil pumping pump by sand.The pumping pump has a longer service cycle than the general pumping pump, thus extending the service life of the pumping pump, which is ideal for conventional well and corrosive medium wells.

Structure and working principle

Oil pump pumping, mainly depends on the plunger assembly in the cylinder to complete oil pumping.During the upper stroke, the pumping rod drives the plunger to move upward, the swimming valve is closed, the pump chamber volume increases, the pressure decreases, the fixed valve is opened, and the downhole oil fluid enters the pump chamber.During the downward process, the pumping rod moves the plunger downward, the fixed valve is closed, the volume of the pump chamber decreases, the pressure increases, the swimming valve is opened, and the oil fluid in the pump chamber is discharged into the upper oil cavity oil pipe of the pump to discharge the oil fluid into the ground conveying pipeline.

| Model | Diameter mm | Stroke mm | Plunger length m | Connection tube OD mm | Rolling ball valve ID | Fix Ball Valve ID |

| 25-125TH | 31.75 | 3~6 | 1.2 | 73.0(2 7/8 TBG) | s∮19 | s∮38 |

| 25-150TH | 38.10 | 3~6 | 1.2 | 73.0(2 7/8 TBG) | s∮25 | s∮38 |

| 25-175TH | 44.45 | 3~6 | 1.2 | 73.0(2 7/8 TBG) | s∮29 | s∮38 |

| 25-200TH | 50.8 | 3~6 | 1.2 | 73.0(2 7/8 TBG) | s∮32 | s∮38 |

| 25-225TH | 57.15 | 3~6 | 1.2 | 73.0(2 7/8 TBG) | s∮35 | s∮38 |