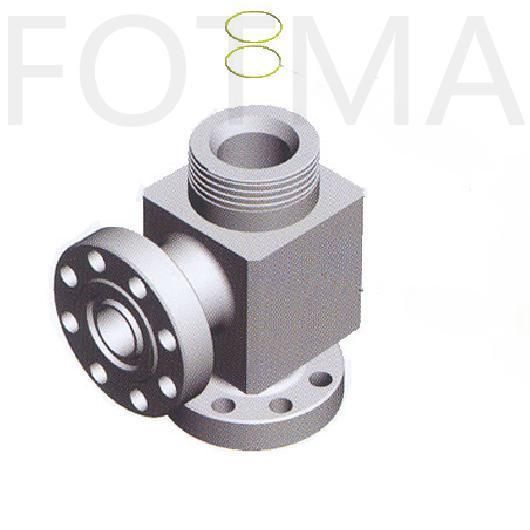

High Quality Choke Valve--Positive Choke Valve/Orifice Choke Valve

Hubei Fotma Machinery Co., Ltd.- After-sales Service:Available Online

- Warranty:Six Months

- Certification:ISO 9001:2015

- Surface Treatment:Polishing

- Centralizer Type:Customized

- Structure:Customized

Base Info

- Model NO.:Customized

- Material:Cast Steel

- Type:Choke Valve

- Applicatiopn:Industry Usage

- Transport Package:Plywood Cases or as Per Customers′ Requirements

- Specification:Customized

- Trademark:FOTMA

- Origin:China

- HS Code:8481804090

- Production Capacity:1000 Pieces,Month

Description

Main technological parameters:

Rated pressure: 2000- 1 5000psi

Working temperature: PU

Working medium: petroleum & natural gas.

Choke bore: φ3 thru φ12

Structural feature:

All pressing parts are made of alloy steel and have enough tensile strength, that ensures the valve safe and reliable at rated working pressure .

Choke is made of carbide with fine grind & erosion resistance properties .

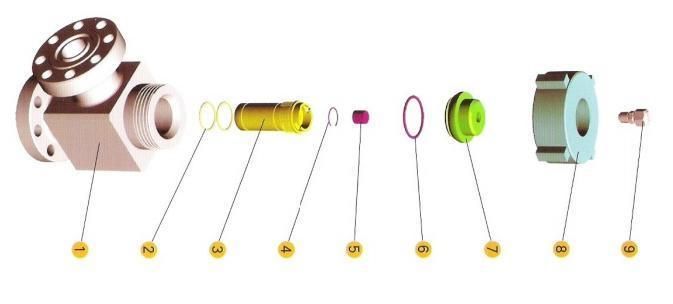

| Item | Component | Qty | Material | Code |

| 1 | Body | 1 | 4130 | SH- CVP- -xx-xx-01 |

| 2 | O-Ring | 2 | NBR | SH- CVP- -xx-xx-02 |

| 3 | Valve Core | 1 | 4130 | SH- CVP- -xx-xx-03 |

| 4 | Retaining Ring | 1 | 1566 | SH- CVP- -xx-xx-04 |

| 5 | Choke Bean | 1 | YG8 | SH- CVP- -xx-xx-05 |

| 6 | O-Ring | 1 | NBR | SH- CVP- -xx-xx-06 |

| 7 | Bonnet | 1 | 4130 | SH- CVP- -xx-xx-07 |

| 8 | Lock Nut | 1 | 1045 | SH- CVP- -xx-xx-08 |

| 9 | Grease Fitting | 1 | Standard | SH- CVP- -xx-xx-09 |

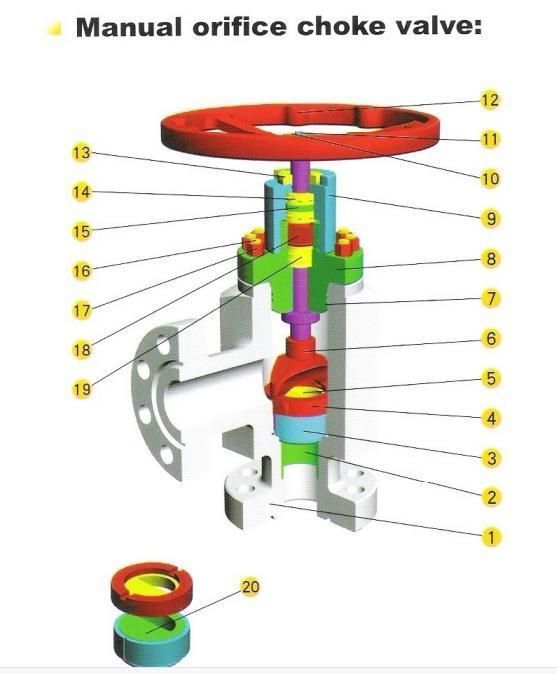

Orifice choke valve

Brief introduction:

Orifice choke valve is molded of two pieces of special carbon tungsten plates with rather ability of erosion resistance. one of which rotates to alter the concentricity between the upper orifice and lower orifice of two plates so as to adjust the flow-rate of fluid or gas.

Application:The valve is used for manifold such as drilling ,fracture,mud circuit,ground high--pressure gas injection/production.

Advantages:It has long working life and ability of erosion/ corrosion resistance in comparing with other choke valves.

| Item | Component | Qty | Material | Code |

| 1 | Body | 1 | 4130 | SH- CVP-xx-xx-01 |

| 2 | Lower Seat Bushing | 1 | 4130 | SH- CVP-xx-xx-02 |

| 3 | Upper Seat Bushing | 1 | 4130 | SH- CVP-xx-xx-03 |

| 4 | Upper Seat | 1 | YG8 | SH- CVP-xx-xx-04 |

| 5 | Stem | 1 | 410 | SH- CVP-xx-xx-05 |

| 6 | Spring | 10 | 1566 | SH- CVP-xx-xx-06 |

| 7 | O-Ring | 2 | NBR | SH- CVP-xx-xx-07 |

| 8 | Bonnet | 1 | 4130 | SH- CVP-xx-xx-08 |

| 9 | Screw Housing | 1 | 5140 | SH- CVP-xx-xx-09 |

| 10 | Washer | 1 | 1035 | SH- CVP-xx-xx-10 |

| 11 | Screw | 1 | Standard | SH- CVP-xx-xx-11 |

| 12 | Handwheel | 1 | 1035 | SH- CVP-xx-xx-12 |

| 13 | Pointer | 1 | 5140 | SH- CVP-xx-xx-13 |

| 14 | Bearing | 2 | Standard | SH- CVP-xx-xx-14 |

| 15 | Split Bushing | 1 | 5140 | SH- CVP-xx-xx-15 |

| 16 | Packing Gland | 12 | 5140 | SH- CVP-xx-xx-16 |

| 17 | Bonnet Nut | 12 | 5140 | SH- CVP-xx-xx-17 |

| 18 | Packing | 1 | NBR | SH- CVP-xx-xx-18 |

| 19 | Bonnet Stud | 3 | 4130 | SH- CVP-xx-xx-19 |

| 20 | Lower Seat | 1 | YG8 | SH- CVP-xx-xx-20 |

The representation of part number:

| SH | --- | XXXX | --- | XX | --- | XX | --- | XX |

| SH | --- | Type | --- | DN | --- | WP | --- | No |

| DN | Code | WP | Code |

| 1-13/16'' | 46 | 3,000psi | 21 |

| 2- 1/16'' | 52 | 5,000psi | 35 |

| 2-9/16'' | 65 | 10,000psi | 70 |

| 3-1/16'' | 78 | 15,000psi | 105 |

| 3-1/8'' | 80 | ||

| 4-1/16'' | 103 |

| Type | Work Pressure | H | L | Maximum Orifice |

| 2-1/16 '' | 2000psi | 148 | 148 | 1 1/2″ |

| 2-1/16 '' | 3000psi | 198 | 186 | 1 1/2″ |

| 2-1/16 '' | 5000psi | 186 | 186 | 1 1/2″ |

| 2-1/16 '' | 10000psi | 230 | 230 | 1 1/2″ |

| 2-9/16 '' | 10000psi | 296 | 282 | 1 1/2″ |

Beaic Technical Parameters for Adjustable Choke Valve (unit:mm):

| Type | Work Pressure | H | L | Maximum Orifice |

| 2-1/16 '' | 3000psi | 238 | 186 | 2″ |

| 2-1/16 '' | 5000psi | 238 | 186 | 2″ |

| 2-1/16 '' | 10000psi | 320 | 230 | 2″ |

| 2-9/16 '' | 5000psi | 330 | 212 | 2″ |

| 2-9/16 '' | 10000psi | 320 | 230 | 2″ |

| 3-1/8'' | 3000psi | 200 | 195 | 2″ |

| 3-1/8'' | 5000psi | 200 | 195 | 2″ |

| Rated Working Pressure | 2000psi thru 1 5000psi | Nominal Size | 2 1/16in. thru 4 1/16in. |

| Product Specification Level | PSL1 thru 3 | Material Class | AA thru FF |

| Performance Requirement | PR1&2 | Temperature Level | PU |