Drilling Fluid Mud Shale Shaker for Trenchless Boring Project

TIANJIN RUILIKE ENGINEERING MACHINERY CO., LTD.- After-sales Service:Longlife

- Warranty:60 Days

- Certification:ISO 9001:2008

- Mesh Shape:Rectangle

- Sieve Mesh Number:20-200

- Layer:Double Layer

Base Info

- Model NO.:100m3,h

- Material:Steel

- Type:Circular

- Transport Package:Wooden Crate

- Specification:100m3,h

- Trademark:RLK

- Origin:China

- HS Code:8431432000

- Production Capacity:500 PCS Per Year

Description

Basic Info.

Model NO. 100m3/h Material Steel Type Circular Transport Package Wooden Crate Specification 100m3/h Trademark RLK Origin China HS Code 8431432000 Production Capacity 500 PCS Per YearProduct Description

| Function | It is a kind of Solid Control Equipment and specialized in desanding and recycling the drilling fluid or mud. The inlet is where the raw mud shall be transfered into, and the outlet shall be connected with the storage tank. |

| Model | RLKJC100 |

| Product name | Integrated mud cleaning system - desander |

| Capacity | 100 m³/h |

| Shale shaker | With double sieves SZS900 (under sieve + upper sieve) |

| Sieve material | High wear resistance stainless steel 304 crevice sieve or polyurethane sieve |

| Cleaning Class | Class 2 - - Vibration screen + centrifugal separation of hydrocyclone |

| Hydrocyclone | DN300 * 1 pcs |

| Total power | 25 kW |

| Slurry pump | Wear-resistant alloy Cr27 |

| Partical size | >60μm |

| Inlet size | 4" |

| Outlet size | 6" |

| Overall size | 3000x2000x2550 |

| Weight | 3200 kgs |

| Operation mode | Remote control, automatic or manual |

More options: 15m3/h, 30m3/h, 50m3/h, 70m3/h, 100m3/h, 150m3/h, 200m3/h, 250m3/h, 300m3/h

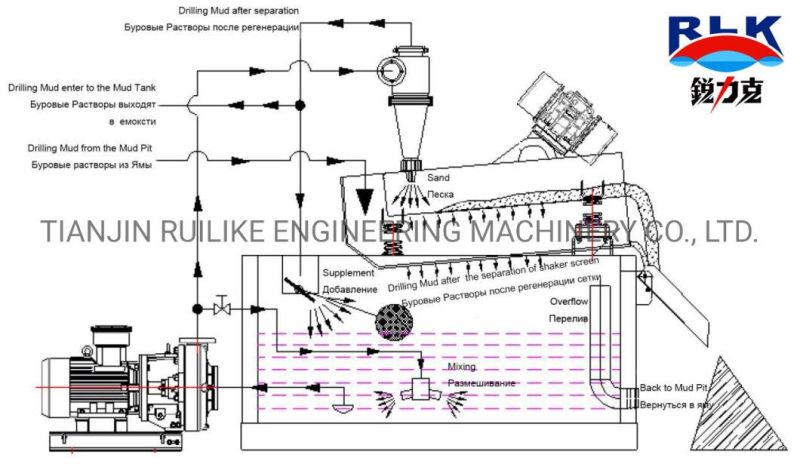

WORKING PRINCIPLE

With the help of the pit pump, the drilling mud in the mud pit enter into the lower screen of the shale shaker, this is the first stage screen processing, large particles of solid phase is expelled, liquid mud leakage into the mud tank under the shale shaker, with the help of the slurry pump on the Mud Recycler, drilling mud in the mud tank enter into the hydrocyclone for the secondary centrifugal separation, solid phase were bigger than 60 microns to separate the back to the upper deck of the top screen and screening out the back, clean mud from upper cyclone discharge, back to the undersize circulating tank for filling slurry discharge enter to the others slurry storage tank for drill rig. In the cyclone circulation tank back fill slurry pipeline set liquid level automatic balancing device which is composed of a floating ball and liquid level frame. When the circulating tank liquid level rises, floating ball follows up, level the flap closed, mud a lot discharges. When the liquid level lower level, level the flap follows open, much slurry goes back to the tank to replenish slurry, mud discharge reduces. When the liquid level under the adjustment level, no longer discharge, all goes back to the tank to fill slurry, reach the status since the circulation system. At the discharge outlet of the slurry pump, one path to the cyclone, and another path is a bypass pipeline that is connected with the mixing nozzle pipeline in the circulating tank, and a valve is provided. When the deposition in the tank increases, the valve can be opened to backwash and stir the deposition in the circulating tank, and the slurry after mixing is pumped into the cyclone for solid-liquid separation again. The schematic diagram is as follows: :

ADVANTAGE OF MUD RECYCLERS/DESANDERS/MUD CLEANERS/SHALE SHAKERS/MUD CLEANING SYSTEM:

1 . Fully purifying the drilling mud is conducive to controlling the performance index of the mud, reducing the sticking accidents and improving thequality of hole making.

2 . Effective separate drilling mud and solids, conducive to improving the working efficiency of hole making.

3 . The repeated use of drilling mud is beneficial to saving slurry materials and reducing construction costs.

4 . Closed-circuit circulation of mud and low water content of slag material are beneficial to reducing environmental pollution.

5 . The integrated product design greatly saves the floor space, compressing the collective and increasing the convenience of transportation.

6 . The returning drilling mud from the drilling hole can be recovered 80-90%, can save sodium soil and other raw materials 40-50%, the discharge of solids moisture content can be controlled within 30%. It can be buried on site.

7 . It reduces the labor intensity of the workers to configure the new pulp and saves the 24 hours hydration time of the new pulp.

8 . Greatly saves the transportation cost of the waste mud without purification and recovery. This cost is particularly evident when drilling into rock formations.

9 . To sum up, the use of the Slurry Separation System is conducive to the related engineering construction of high quality, efficient, economic, civilized, is a friendly environmental protection machinery products.