Hot Sale! Downhole Mud Motor

Glorytek Industry (Beijing) Co., Ltd.- Manufacturing Process:Casting

- Surface Treatment:Galvanized

- Operation Pressure:Atmospheric Pressure

- Material:Alloy

- Product Type:5lz57*7.0

- Recommended Hole Size:83-121mm

Base Info

- Model NO.:5LZ57*7.0

- Input Flow Rate:1.5-3.5L,S

- Pressure Loss:3.2MPa

- Bit Speed:185-430r,Min

- Working Torque:200n.M

- Delay Dynamic Torque:350n.M

- Output Power:4.3-10.1kw

- Drilling Weight:5kn

- Transport Package:Standard

- Specification:Length2822mm

- Trademark:GLORYTEK

- Origin:Beijing China

- Production Capacity:20000piece,Year

Description

Spec.

Recommended Hole Size

Input Flow Rate

Pressure Loss

Bit Speed

Working Torque

Delay Dynamic Torque

Output Power

Drilling Weight

Max Drilling Weight

Joint Thread

Length

Unit

mm

In

L/S

Mpa

r/min

N.m

N.m

KW

KN

KN

In

In

mm

5LZ57×7.0

83-121

31/4-43/4

1.5-3.5

3.2

185-430

200

350

4.3-10.1

5

10

11/2REG

11/2REG

2822

5LZ73×7.0

83-121

31/4-43/4

2-4

3.2

80-160

615

1077

5.8-11.5

12

25

23/8REG

23/8REG

3423

9LZ89×7.0

105-143

41/8-55/8

3-8

3.2

147-392

504

882

8.64-23

20

30

27/8REG

27/8REG

2911

5LZ95×7.0

114-150

41/8-57/8

5-12

3.2

140-320

710

1240

10.5-25

21

40

27/8REG

27/8REG

3920

5LZ120×7.0

152-200

6-77/8

8-16

3.2

80-180

1850

3200

23-47

64

106

31/2REG

31/2REG

5039

5LZ165×7.0V

245-244

81/8-95/8

18-30

3.2

111-167

4440

7770

57.6-86.4

80

160

41/2REG

41/2REG

7408

5LZ165.5×7.0V

215-244

81/8-95/8

18-30

4.0

120-180

5135

8987

72-108

90

180

41/2REG

41/2REG

7748

5LZ172×7.0V

215-244

81/8-95/8

18-30

4.0

120-180

5135

8987

72-108

90

180

41/2REG

41/2REG

7391

5LZ172.5×7.0V

215-244

81/8-95/8

20-35

4.0

115-180

6452

11299

86.4-151.2

100

200

41/2REG

41/2REG

8031

7LZ172.5×7.0V

215-244

81/8-95/8

20-35

4.0

75-180

6527

11420

59.5-108.6

80

160

41/2REG

41/2REG

8631

Usage :It is one kind of positive displacement downhole motor, with working principle is to convert the high pressure fluid power of mud into mechanical energy for bit rotation. It is widely used in oil field and mine directional well and horizontal well, cluster Wells and vertical Wells, drilling, deflecting, adjusting azimuth, coring, reaming, side tracking and workover treatment, and also applied in some special operations as compound drilling and traversing, etc.

Specifications : We can produce series of downhole motors in different sizes, as Φ57(21/4"),Φ73(23/4"),Φ89(31/2"),Φ95(33/4"),Φ120(43/4"),Φ127(5"),Φ165(61/2"),Φ172(63/4"),Φ178(7"),Φ185(71/4"),Φ197(73/4"),Φ203(8"),Φ216(81/2"),Φ244(95/8"), etc.

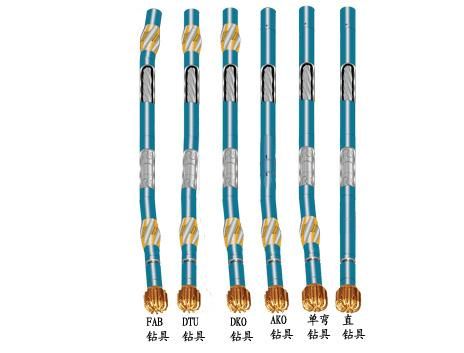

A Variety of Types & the Capabilities In accordance with the actual drilling needs, we push out high, midiem and low speed downhole motors, of a variety of types with different functional configuration and application for all working conditions.

1. Standard type Standard motor, mud lubricating transmission shaft, straight, single and double bent.

2. Long type The torque is increased by 30%to 60%than standard ones, mud lubricating transmission shaft, straight, single and double bent.

3. High flow rate type The adoption of hollow rotor and different sizes of hard alloy jet nozzle to increase the incoming flow and bit power.

4.High deflection type The unique structure design makes the overall length shorter and bent housing closer to the bit, deflection rate reach up to 1/m, so as to keep good working conditions.

5. High temperature resistance type The motor stator is made of superior quality high temperature resistant rubber, which enables the motor to perform stably in the well bottom at max.175ºC.

6. Oil-sealed transmission shaft type It improves the working condition of thrust bearing and radial bearing, and increases the life span of each single trip.

7. Bend angle adjustable type We equip the motors with adjustable bend housing in different types and sizes, and through which before dropping we can adjust the bend angle.

8. Saturated saltwater mud resistance type The special coating on the rotor with strong ability of anti-corrosion and wear-resistance enables the motor to work stably for a long time in the condition of saturated saltwater mud.

9. Impact Resistance Type We adopt a series of shock absorbers to lighten or eliminate bit jumping and impact shock occurring in drilling, protect the drilling tools avoiding damage, increase service life and ensure the drilling safe and efficient. ( style impact resistance downhole motor is our new technology patent products)

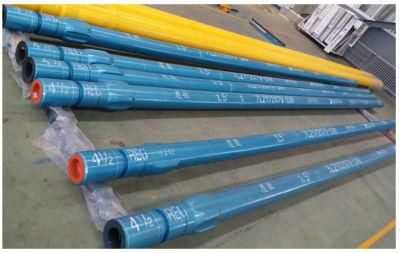

Packing

Related Product

Our Company & Service

Glorytek Industry (Beijing)Co.,Ltd., located inBeijing,China, is an integrated corporation specialized in manufacturing and exporting top quality drilling equipment and drilling parts for decades. We are supported and assisted by a highly experienced team of designers and engineers that enable us to complete all the assigned projects successfully as per the specified requirement from our clients.

Customer photos

FAQ

Q: How can we choose a suitable water well drill rig?A: We normally recommend a suitable model according to drilling depth, drilling hole dia. and layer condition on site. Q: Are you a factory or a trading company ?

A: We are an integrated corporation specialized in manufacturing and exporting.

Q: What is your payment terms?

A: We can accept T/T,L/C.

Q:.What is your MOQ? How long is the delivery time?

A: Our MOQ is 1 sets. Normally for drill rig, the delivery time is about 25-30 days after receiving payment, the drilling tools would be about 3-5 days.

Q:. How long is the warranty?

A: The guarantee period for mainframe is one year (excluding the quick wear parts).

Q: Can we print my Logo on the products?

A: Yes, we can. We support OEM .

Contact

Sunny Dong(Sales Representative)

Glorytek Industry (Beijing) Co., Ltd.Address:No.B-2507, DongWeiCheng, GuanZhuang,Chao Yang District, Beijing, China.

Website: glorytek.en.made-in-china.com / glorytek.en.made-in-china.com