Centrifugal Pump Portable Fuel Transfer Electric Gasoline Engine Oil

Zhenjiang Boral Machinery and Equipment Co., Ltd.- Certification:CE, ISO 9001:2000

- Mesh Shape:New Hole

- Sieve Mesh Number:40-200

- Layer:Multilayer

- Material:Stainless Steel

- Type:High Frequency

Base Info

- Model NO.:KNS

- Warranty:18mths

- Transport Package:Wood Box

- Specification:customized

- Trademark:kes

- Origin:China

- HS Code:8431431000

- Production Capacity:10000sets,Year

Description

Basic Info.

Model NO. KNS Warranty 18mths Transport Package Wood Box Specification customized Trademark kes Origin China HS Code 8431431000 Production Capacity 10000sets/YearProduct Description

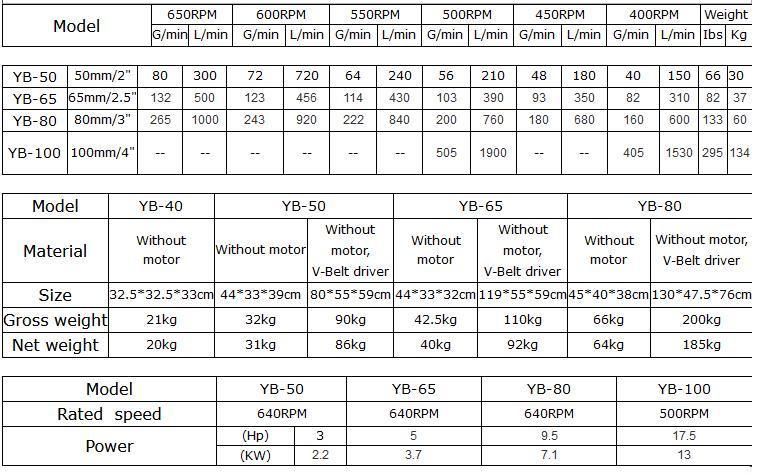

Excellent performance and extensive lineup of leading magnetic drive pump designs.Maximum flow range from 150L/min to 1000L/min

to meet a wide spectrum of applications.

Magnet drive designs have become the standard for applications requiring corrosion resistant pups.Our magnet drive pump designs offer

a wide range of capabilities from compact OEM configurations to our large chemical process pump series.This broad range of magnet

drive pump capabilities is unmatched in the industry making us the leader in magnet drive pump technology

- Leak free, seal-less construction

- Simple, modular construction for eas of maintenance.

- Non-metallic chemically inert materials offer excellent resistance to corrosive fluids.

Self-radiating structure

Through heat-dispersion holes provided in the fixed portions of the impeller and the magnet capsule, liquid is circulated under pressure between the spindle

and bearing to reduce friction heat transmission and prevent thermal deformation.

Non-contact structure

The drive magnet and driven magnet are carefully positioned so that their strong magnetic field limits rear thrust contact of the magnet capsule parts,even

during dry running. As a result, heat generation is greatly reduced and liquid circulation is maintained.

Volute casing divided into two sections

The CSM series is the first resin magnet pump which uses the pump casing divided into he front casing and the rear casing to form a vortex chamber as an ideal

form. Therefore, internal leakage is kept to a minimum and overall hydraulic efficiency is enhanced.

Robust structure

All stress bearing portions, such as the front and rear casings, are reinforced by means of ribs to improve the pressure resistance and the mechanical strength

of the pump. The bearing is not only fixed by conventional press fit but is also sandwiched between the abutting portion in the depth of magnet capsule and the

rear end of the impeller to improve its reliability under high temperature.