PDC Cutter 1613 PDC Rock Bit Cutter Insert

Zhuzhou Better Tungsten Carbide Co., Ltd.- Manufacturing Process:Forging

- Surface Treatment:Polishing

- Operation Pressure:Atmospheric Pressure

- Material:Tungsten Carbide Base+PCD Layer

- Usage:Oil,Gas Drill Bit,Coal,Rock Drilling,Well Drilling

- Shape:Ball Nose and Flat Nose

Base Info

- Full Name of PDC:Polycrystalline Diamond Cutters

- Name:PDC Cutter 1613 PDC Rock Bit Cutter Insert

- Transport Package:in Plastic Box

- Specification:1916, 1916, 1913, 1613, 1610, 1313, 1308.

- Trademark:ubt

- Origin:China

- Production Capacity:500000

Description

Basic Info.

Full Name of PDC Polycrystalline Diamond Cutters Name PDC Cutter 1613 PDC Rock Bit Cutter Insert Transport Package in Plastic Box Specification 1916, 1916, 1913, 1613, 1610, 1313, 1308. Trademark ubt Origin China Production Capacity 500000Product Description

PDC cutter 1613 pdc rock bit cutter inserts

Product description:

There are usually have two shape of PDC buttons.

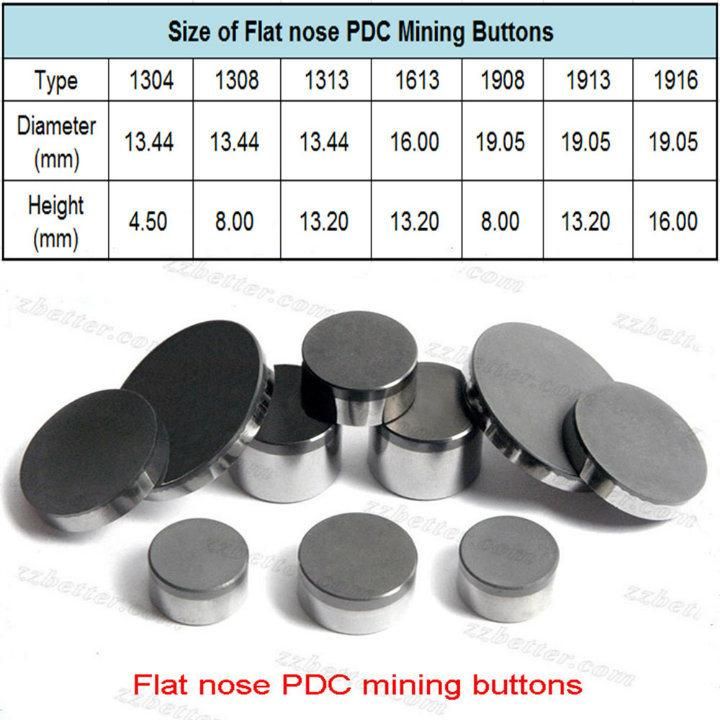

Flat nose PDC buttons:

Flat nose PDC buttons made of the diamond and carbide two parts, is in a specific high temperature and pressure conditions sintering from the super-hard composite materials. Products can be used for petroleum geologic drill bits, suitable for drilling in soft and soft upper strata.

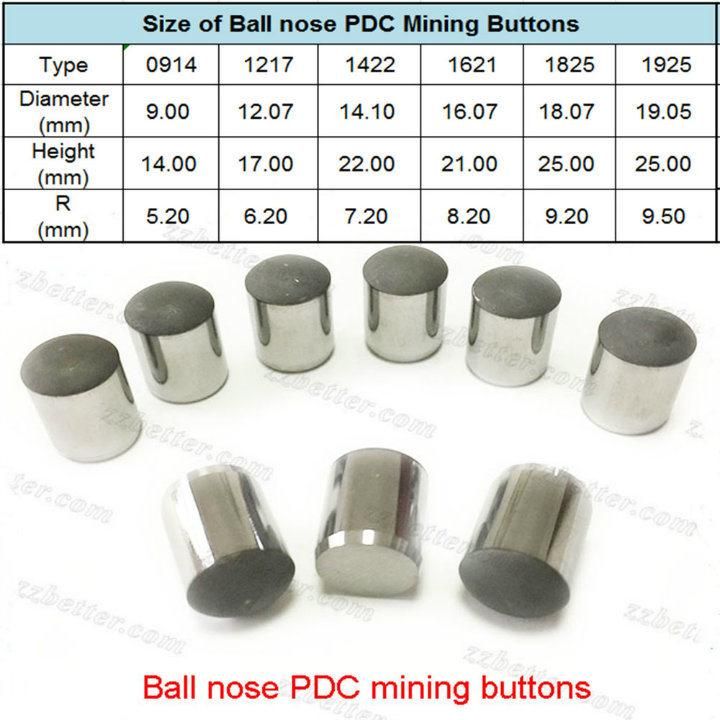

Ball nose PDC buttons:

Ball nose series PDC buttons combines the high toughness of cemented carbide and high wear resistance of diamond, choose the excellent impact geometry, in a constant high temperature and pressure synthesis, with a stronger impact resistance and wear resistance. The Products can be used for roller bit, mine submersible drill, suitable for hard formation and complex formation drilling.