Oilfield Chemical Diaphragm Leak-Proof Pump Drilling Tools

Liaoning Tolian Technology Development Co, . Ltd- Warranty:3 Month

- Manufacturing Process:CNC Milling

- Surface Treatment:Without Processing

- Operation Pressure:Atmospheric Pressure

- Material:Carbon Steel

- Pressure:Low Pressure

Base Info

- Power:Pneumatic

- Advantages:Explosion-Proof , Zero Leak , Stall-Fr

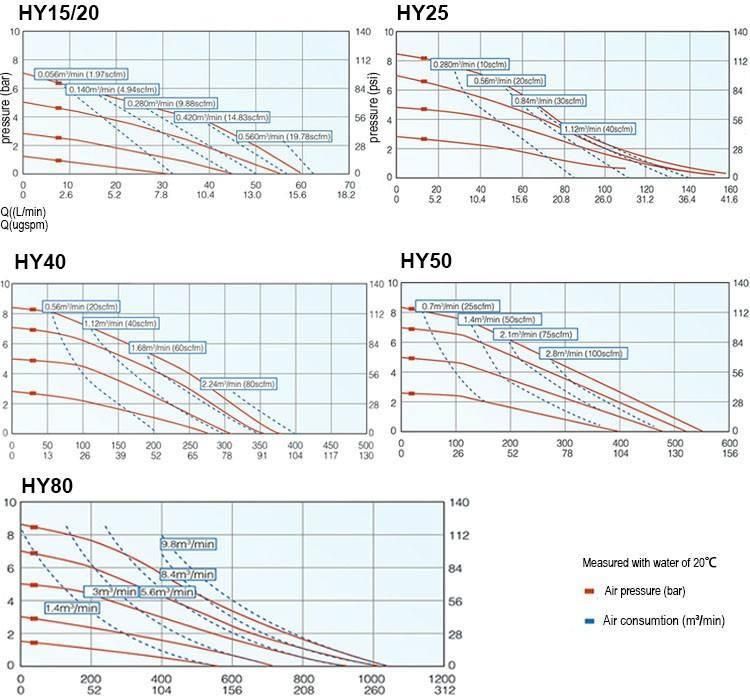

- Max Suction Lift:Dry 4m ;Wet 7.6m

- Max Flow Rate:57L,Min

- Max Head:84m

- Certificate:CE

- Theory:Reciprocating Pump

- Structure:Diaphragm Pump

- Transport Package:Wooden Case

- Specification:According to the custom

- Trademark:Tolian

- Origin:China

- HS Code:8431431000

- Production Capacity:1000piece,Month

Description

Oilfield Chemical Diaphragm Leak-proof Pump

Product Description

Pneumatic Diaphragm Pump Advantages:

- Idling ,Self-priming , Submerse capability.

- Provide stall-free, ice-free zero leak operation.

- Epoxy-coated air section for tough environmental conditions.

- Low shear force , not easy to damage the material structure.

- Bolt joint design provides even sealing pressure for optimal performance

- Modular air valve,low pulsation operation,providing smooth and rapid changeover.

- No electricity . It's safe and realiable while using in the flammable and explor place .

- Diversity of material,no rotating parts,applicable to various erosive situations.

- Can pump corrosive , volatile, flammable, poisonous fluids with particles and high viscosity.

- Delivery lift and flow can pass the pneumatic valve open to realize the stepless adjustment.

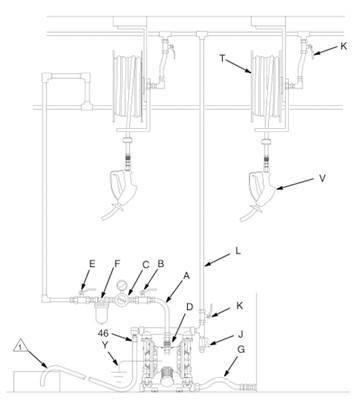

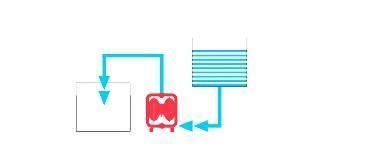

Fuel Dispenser System

A. Air supply line

B. Bleed-type master air valve

C. Air regulator

D. Air line quick disconnect

E. Master air valve

F. Air line filter

G. Fluid suction line

J. Fluid drain valve

K. Fluid shutoff valve

L. Fluid line

T. Hose reel

V. Fuel dispense valve

Y. Ground wire

46 Pressure relief valve

AODD pumps are suitable for an endless variety of applications . Our pumps can be deployed in fixed installations within a process flowsystem, or used as portable or mobile units that can be transported to where it is to be used.

Pump, self-priming

Pump, self-primingAODD pumps are dry self-priming. Depending on the pump specification a suction lift of up to 8 m

Pump with positive suction

Pump with positive suctionDepending on the pump type, the suction side inlet pressure may need to be limited to a max. pressure

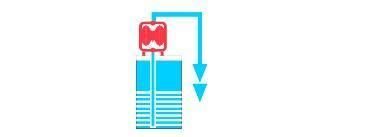

Pump, submerged

Pump, submergedAODD pumps can be totally submerged in the pumped medium. The exhaust outlet must remain above the fluid level.

Pump for drums

AODD pumps can be directly mounted on drums or containers.