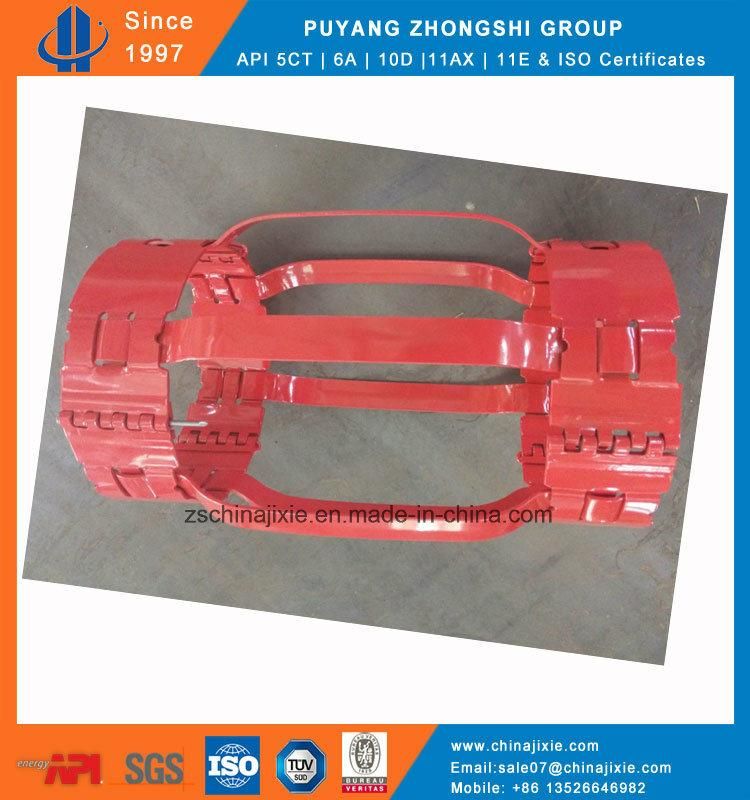

Oilfield Equipment 9 5/8′′ Hinged Non Welded Bow Spring Casing Centralizer

Puyang Zhongshi Group Co., Ltd.- Certification:ISO 9001:2000, API

- Surface Treatment:Spray-Paint

- Centralizer Type:Elastic

- Material:65mn Spring

- Type:Centralizer

- Centralizers Type:Hinged Non Welded Bow Spring Centralizer

Base Info

- Model NO.:ZS105

- APP:Well Drilling

- Sample:Avaliable

- OEM:Avaliable

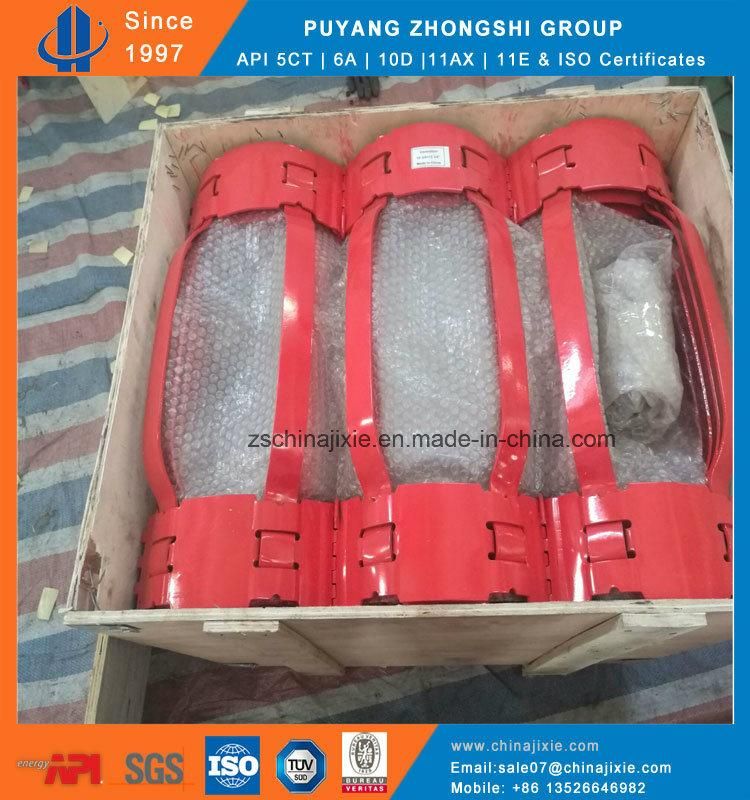

- Transport Package:Wooden Case

- Specification:4-1,2" to 20"

- Trademark:ZS

- Origin:Henan

- Production Capacity:20000 Piece,Pieces Per Month

Description

Basic Info.

Model NO. ZS105 APP Well Drilling Sample Avaliable OEM Avaliable Transport Package Wooden Case Specification 4-1/2" to 20" Trademark ZS Origin Henan Production Capacity 20000 Piece/Pieces Per MonthProduct Description

Oilfield Equipment 9 5/8'' Hinged Non Welded Bow Spring Casing CentralizerInterlocking design between the end collar

Made of alloy steel with uniform hardness

Features of hinged bow centralizer non welded

Bow springs are slightly larger than the wellbore.

The highest restoring force and the lowest starting force.

The Heat Treated bows enables these centralizer to provide best centralization as well as help in faster running of casing.

The bows are available in a range to accommodate any well profile.

The End Collars have hinges which makes it in two halves.This enables them to be assembled at site.

Size: 4-1 / 2" to 20'', custom size is avaliable.

Centrlizers parameter:

| Model | Hooping In-Dia. | Hooping thickness | Total length | Max.Out-Di | Amount of spring |

| (in) | (mm) | (mm) | (mm) | (mm) | (mm) |

| 5-1/2" x 8-1/2" | 142-148 | 3~5 | 650±50 | 225±5 | 5 |

| 7" x 9-5/8" | 181-186 | 3~5 | 650±50 | 255±5 | 6 |

| 7" x 8-1/2" | 181-186 | 3~5 | 650±50 | 235±5 | 6 |

| 8-5/8 x 12-1/4" | 223-228 | 3~5 | 650±50 | 330±5 | 8 |

| 9-5/8 x 12-1/4" | 250-255 | 3~5 | 650±50 | 330±5 | 8 |

| 10-3/4 x 12-1/4" | 274-276 | 3~5 | 650±50 | 330±5 | 9 |

| 13-3/8"x17-1/2" | 342-347 | 3~5 | 650±50 | 450±5 | 11 |

| 18-5/8"x24" | 475-477 | 3~5 | 600±50 | 610±5 | 12 |

| 20"x26" | 509-511 | 3~5 | 600±50 | 660±5 | 12 |