Water Glass Sand Cast Hammer Block Casting

NINGBO QS MACHINERY INC.- Certification:ISO 9001:2000

- Surface Treatment:Without Processing

- Material:Cast Steel

- Transport Package:Plywood Box

- Specification:ASTM, AISI, SAE, UNS, NF, DIN-EN, JIS, KS, SS, BS

- Trademark:QS machinery

Base Info

- Origin:Ningbo, China

- Production Capacity:600ton,Month

Description

Basic Info.

Origin Ningbo, China Production Capacity 600ton/MonthProduct Description

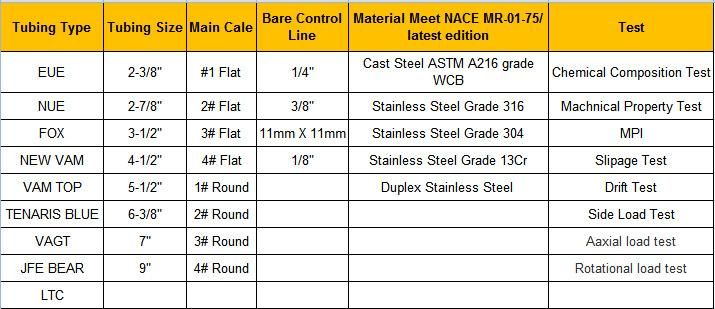

Cross Coupling cable protectors are well-engineered to safely convey and efficiently secure virtually any configuration of control lines or cables into or out of well-bores. More then 1000 types of Cross Coupling cable protectors were custom made and developed for a wide range of tubing(coupling) type & sizes, cable types & sizes. Material and design will be custom made upon the projects' requirements.

APPLICATIONS

• ESP cable

• Subsurface safety valves control line

• Chemical injection line

• Permanent Gauges

• Intelligent Wells

• Fiber Optic

• Coiled tubing

DESIGN FEATURES and OUR ADVANTAGES

• Streamlined design and beautiful structure

• Tubing sizes from 2 3/8" O.D. to 7" O.D.

• Fast action for design and short lead time

• Separate channels for flat, round, or square cables and control lines in one cross coupling protector

• Material of Cast steel, Stainless Steel, Duplex Stainless Steel are available

• One piece assembly with no loose fittings.

• Galvanized coating or Electrophoretic paint for maximum rust protection

• Custom-made upon request

We have 10 years exeperience in the manufacturing of cross coupling protector/downhole cable protector/control line protector.

1)Up-to-date steamlined designs for the cross coupling protector make the installation in high efficiency and low costs.

2)Our own foundry and machining shop equiped with automatic shell making line and manual line and can work the high volume order and small order in the same time,and indure fast delinery in stable quality .

3)A stable and fluent processure and full set of quality standars were established during our 10 years' production of cable protectors.

4)Heat numbers will be made on body of the protectors to track the batch quality well ;pre-pouting material tests and post-pouring material tests and post-pouring material tests will be done to insure the proper material,and test bars will be done each production for customers' tests.

5)We have production capacity of 25000 sets per month.

6)All kinds of testing can be done in house,such as MPI, drift test,slipage test,axial load test ,rotational load test as well as the crush load test.

7)Tech people in full energy are alwarys prepared well to provide high quality service to the customers.

We are always ready to meet with the customers' need,and save the costs and time.