Mud Pump Spare Parts Valve &Seat Assembly

HEBEI XINHUAFA PETROLEUM MACHINERY CO., LTD.- Manufacturing Process:Forging

- Surface Treatment:Spray-Paint

- Operation Pressure:Atmospheric Pressure

- Material:Ceramic

- Cetification:API

- Hardness(Hra):180

Base Info

- Specifications:60 to 300mm

- Yield Strength:>450MPa

- Tensile Strength:>610MPa

- Outer Sleeve:Forged Steel 45#

- Inner Sleeve:Zirconia

- Name:Zirconia Liner

- Package:Standard

- MOQ:3

- Model:F Series,3nb Series,etc

- Theory:Centrifugal Pump

- Transport Package:Wooden Box and Sea Shipment

- Specification:standard

- Trademark:xinhuafa

- Origin:Cn

- HS Code:841391000

- Production Capacity:50000sets,Per Year

Description

Name of Parts

Service Life (hours)

Valve

>600

Valve Seats

>600

Valve Nut

>1800

Valve Rubber

>300

Valve Spring

>600

Application Pumps:

EMSCO

F500, F800, F1000, FB1300, FB1600

GARDEN DENVER

PAH, TEE-5, PZ-7, PZ-8, PZ-9, PZ-10, PZ-11

NATIONAL

JWS165/340, JWS400, 7-P-50, 8-P-80, 9-P-100, 10-P-130, 12-P-160

OILWELL

A-560-PT, A-600-PT, A-850-PT, A-1100-PT, A-1400-PT, A-1700-PT

IDECO

T500, T800, T1000, T1300, T1600

F-SERIES (China Made)

F500, F800, F1000, F1300, F1600, F1600L, F1600HL

3NB-SERIES (China Made)

3NB-500, 3NB-800, 3NB-1000, 3NB-1300, 3NB-1600

All three of these property advantages translate to lower ownership costs. The improved wear directly extend the service life of the sleeve, while the improved impact strength reduces significantly the costs of replacing broken liners in the field. The surface finish improvements, meanwhile, have an indirect effect. The finer surface finish means less friction with the elastomer-and-metal pump pistons, which in turn extends piston life and reduces pump-cooling requirements.

Company profile

Hebel Xinhuafa Petroleum Machinery Co. LTD was established in 2006,with 5000m2 plant.The company focuses on R&D of mud pump fittings and several R&D results were horned with awards as well as patented for invention. The company is engaged in product design, manufacturing and service on all the quality oilfield replacement parts, including mud pump fluid end parts including Fluid end modules, liners, pistons, valves,&seats, extension rods, piston rods, valve covers etc.

The company holds a professional technical team and is equipped with advanced machineries,improving the technical skills and updating product quality,

Our products are certified by ISO9001 quality control. We supply products not only our oilfields company of domestic, but also dozens of countries all over the world, such as USA, Canada, Indonesia and Iran. With several years' persistence, we are widely accepted as a professional supplier of high quality mud pump cylinder liners and other parts in fluid end modules.

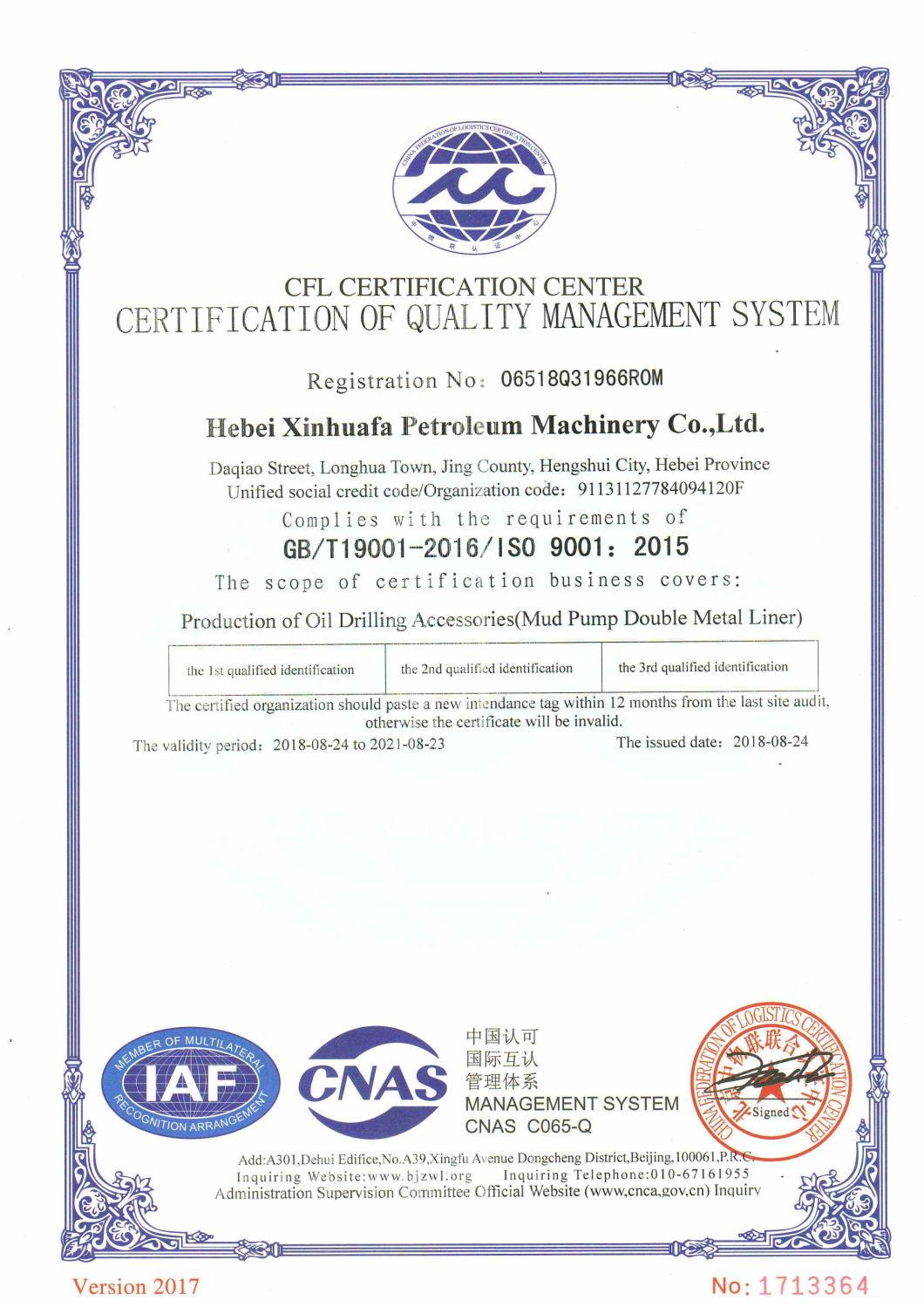

Certifications:

If interested,please contact me: