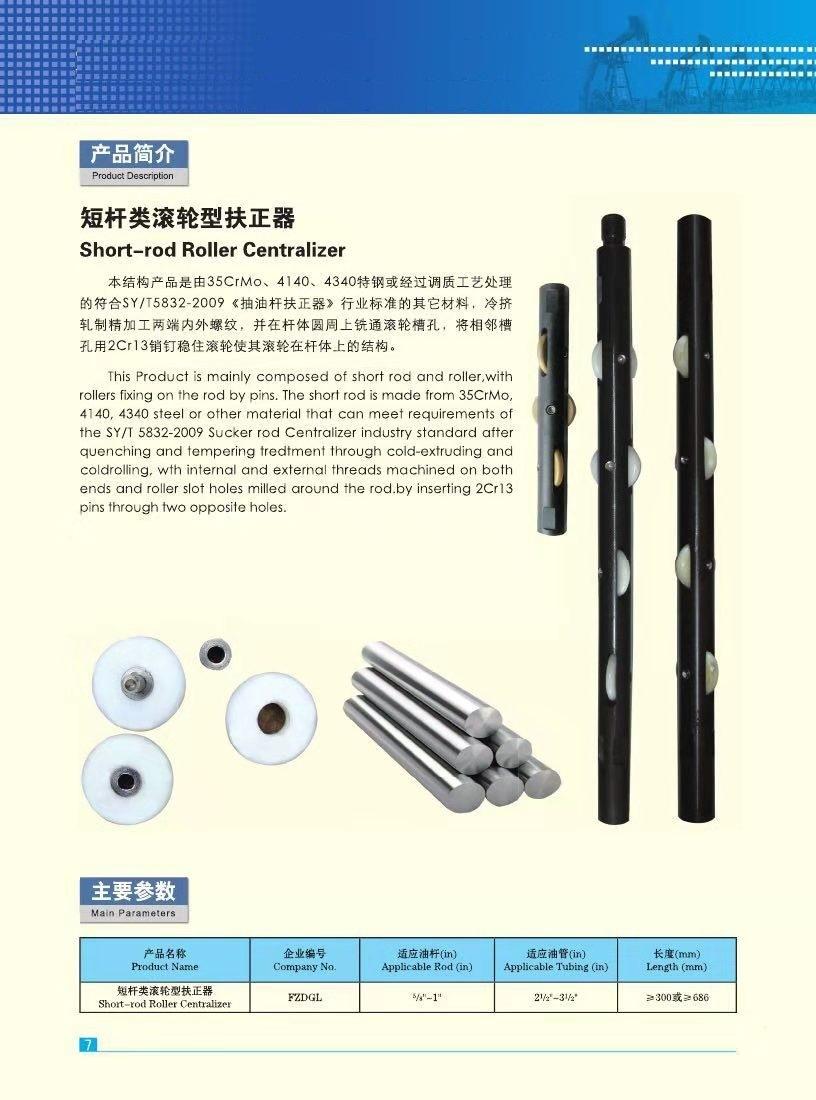

Short-Rod Roller Centralizer for Sucker Rod

Puyang Zhongshi Group Co., Ltd.- After-sales Service:Yes

- Warranty:1 Year

- Manufacturing Process:Forging

- Surface Treatment:Galvanized

- Operation Pressure:Atmospheric Pressure

- Material:Alloy

Base Info

- Model NO.:5,8′′-1′′

- Transport Package:Wooden Box

- Specification:5,8′′-1′′

- Trademark:Zhongshi, China

- Origin:Henan, China

- Production Capacity:60, 000pieces,Year

Description

DIMENSIONS(INCH)

Diameter

Length

Length of the groove

5/8''ROD/2-3/8''TUBING

1.50

27

1.80

3/4''ROD/2-3/8''TUBING

1.50

27

1.80

5/8''ROD/2-7/8''TUBING

1.50

27

2.25

3/4''ROD/2-7/8''TUBING

1.50

27

2.28

7/8''ROD/2-7/8''TUBING

1.625

27

2.28

1''ROD/2-7/8''TUBING

2.0

29

2.28

3/4''ROD/3-1/2''TUBING

1.50

31

2.75

7/8''ROD/3-12''TUBING

1.625

31

2.75

1''ROD/3-1/2''TUBING

2.0

31

2.75

3. Temperature Caution

Standard models are for applications in wellbore temperature up to 175°F. (fitted with glass-fiber reinforced nylon 6 wheels), For service in higher temperature, Special metal wheels are used.

4. Materials

Guide/Coupling Body

Standard guide/coupling bodies are machined from 35CrMo.

Special Material

Other metals such as steel are available on Special 'order to meet some

specifications for extra strength and/or corrosion resistance,

Wheel and Roll Pins

Wheels are set on stainless Steel journals and roll pine, Standard wheels, for applications up to 175°F are made of glass-fiber reinforced nylon 6

5. Parts of roller centralizer for sucker rod

NO

PART NO

NAME

QTY

MATERIAL

1

RG-01

Wheel

4

Glass-fiber Reinforced Nylon 6

2

RG-02

Roll pin

4

Stainless steel

3

RG-03

Coupling body

1

35CrMo

Wheeled rod guides centralize the rod string and reduce friction during stroking, and also reduce wear on sucker rods and tubing.