Low Pressure Petroleum and Gas Recovery System for Offshore Platform

Shandong Wintech Technology Co., Ltd.- Certification:ISO 9001:2008, ASME

- Power Source:Self Containedcapacity

- Operation Pressure:Atmospheric Pressure

- Applicable Medium:Natural Gas, Crude Oil

- Structure:Vertical

- Material:Stainless Steel

Base Info

- Model NO.:WTKJLPCRS7

- Application:Hydrocarbon Recovery From Flare Gas

- Inlet Pressure:5~10 Bar

- Inlet Temperature:6~70 Degree

- Capacity:20~100 Barrels,Day

- Transport Package:Polywood Box

- Specification:7x7x15M

- Trademark:NGL

- Origin:Malaysia

- HS Code:8419609090

- Production Capacity:10 PCS,Year

Description

Basic Info.

Model NO. WTKJLPCRS7 Application Hydrocarbon Recovery From Flare Gas Inlet Pressure 5~10 Bar Inlet Temperature 6~70 Degree Capacity 20~100 Barrels/Day Transport Package Polywood Box Specification 7x7x15M Trademark NGL Origin Malaysia HS Code 8419609090 Production Capacity 10 PCS/YearProduct Description

About the Petroleumand Gas Recovery System (LP-CRS)

The LP-CRS is currently the only system in the world that is able to attract valuable hydrocarbon condensate from very low pressure gas including flare gas in a compact and self-contained unit suitable for both onshore and offshore facilities. The technology enhances the recovery of stabilized crude by 10% to 30% and reduces greenhouse gas emission by approximately 15-30% .

Consisting of a series of heat exchangers, a cold separator and a stabilizer column ,the system uses the JT cooling coupled with evaporative cooling effect that reduces the temperature of associated gas to strip the heavy ends of the gas stream. The JT cooling effect is achieved either via a JT valve or a turbo expander. The condensate stripped after cooling is removed from the gas stream in the cold separator after which it is stabilized in the column. All the water knocked-out during cooling is reinjected into the cold gas stream prior to heat exchange with the inlet associated gas stream. The combination of JT cooling and the evaporation of water enables very efficient cooling of the inlet associated gas stream which is the key to the high performance of condensate extraction.

Benefits

Condensate recovery from gas streams in the typical range of 50 to 100 barrels per MMSCFD of gas depending on fluid composition,

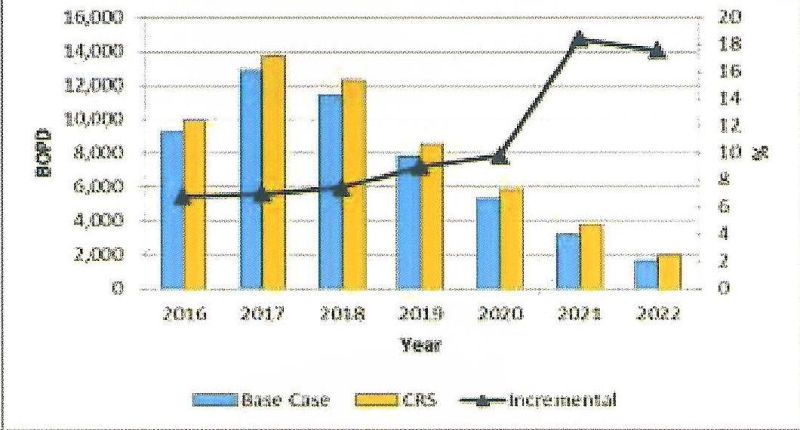

YELLOW: CRS installed BLUE: NO CRS installed

Increase the API of crude (better quality crude)

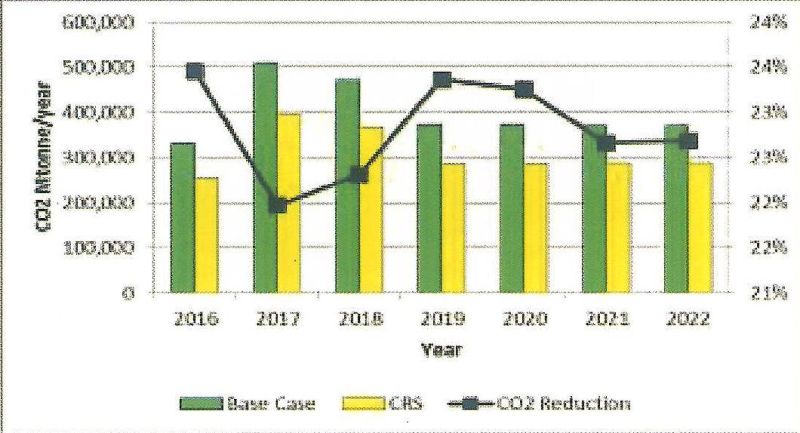

Reduce Greenhouse Gas (CO2) emissions by 20% to 30%.

YELLOW: CRS installed BLUE: NO CRS installedSelf-contained, compact and light weight.

None or minimal rotating equipment resulting to high availability, easy operation and low maintenance.

LP-CRS comes together with hydrate inhibition and anti-freeze agent (MEG) which is recovered in the process.

Improved crude quality and reduce wax deposition for fields facing wax issues

Application

LP-CRS unit can be applied on the flare/vent system.

The system is suitable for both onshore and offshore installations particularly for facilities

where it is not economically viable to install a gas plant with NGL or LPG extraction facilities.

The Joule-Thompson (JT) device for LP-CRS can either be a JT valve system or turbo-expander system, LP-CRS (T).

TRACK RECORD

Topside Engineering, Procurement &Construction(EPC)of theLP-CRS for

MISC MAMPU1 LPV for Anjung Kecil Field, OffshoreSarawak, Malaysia

Operating Envelope:

Max Oil: 8,000 BOPD

Max Gas: 15 Mmscfd

Temperature: 70°C

Temperature: 6°C

Inlet Pressure: 5 to 10 barg

Package Dimensions:

Length: 7.0m

Width : 7.5m

Height: 15m

Package Dry Weight : 80 metric tons

Customization is Avaliable :

We can specially customize products if you tell us any special requests, such as spare parts, cylindricaltank, material, output, pump. ..

TECHNICAL TEAM

OUR WORKSHOP

PACKAGING & DELIVERING