300m3/H Drilling Mud Recovery System/Mud Recycling Facility for a Slurry Balance Pipe Jacking

TIANJIN RUILIKE ENGINEERING MACHINERY CO., LTD.- After-sales Service:Lifelong

- Warranty:Lifelong

- Certification:CE, ISO9001:2015

- Power Source:Electric

- Operation Pressure:Atmospheric Pressure

- Material:Alloy

Base Info

- Model NO.:RLKJC300

- Type:Drilling Fluid Shale Shaker

- Trenchless:Mud Recycling System

- Mud Cleaning Facility:Desander

- Transport Package:Unpacked

- Specification:300m3,h

- Trademark:RLK

- Origin:Made in China

- HS Code:8474100000

- Production Capacity:60

Description

accroding inspection report of geology to Option pre-vabritor,and the system design will be changed as designed

ADVANTAGE OF SLURRY SEPARATION SYSTEM

- High purification and sand removal efficiency, 0.06mm particle size up to 95%, 0.03mm particle size up to 60%;

- Simple operation of linear shale shaker failure rate is low, easy installation, use and maintenance, dehydration effect is good; Screen adopts 304 stainless steel slot mesh, more durable.

- The vibration force of shale shaker, screen surface angle and mesh size can be adjusted according to the working conditions, so that it can maintain good screening effect in various working conditions.

- The light and high speed abrasive slurry pump has the advantages of advanced structure, high degree of universality, reliable operation and convenient installation and disassembly and maintenance. The seal adopts mechanical seal and double seal, which fully guarantees the sealing performance of the pump.

- The hydraulic cyclone with advanced structure has excellent mud and sand separation index. The material is wear-resistant, corrosion-resistant, light in weight, convenient in operation and adjustment, durable and economical, suitable for long-term maintenance free use under harsh working conditions.

- The liquid level automatic balance device of the equipment can not only keep the liquid level of the slurry storage tank stable, but also realize the repeated mud treatment and further improve the purification quality. The liquid level automatic balance device can keep the liquid level automatically and achieve complete unattended.

- Products of our company on the system for slurry pump and sand pump liquid level is set liquid level electronic control system, when the liquid level to dangerous level, can be controlled into sand slurry pump or pump automatic start-stop, the control system only when abnormal level within the system to start, will not start the normal operation of the process, make the equipment in use process more added a insurance function, effectively prevent overflow pulp slurry dry pulp.

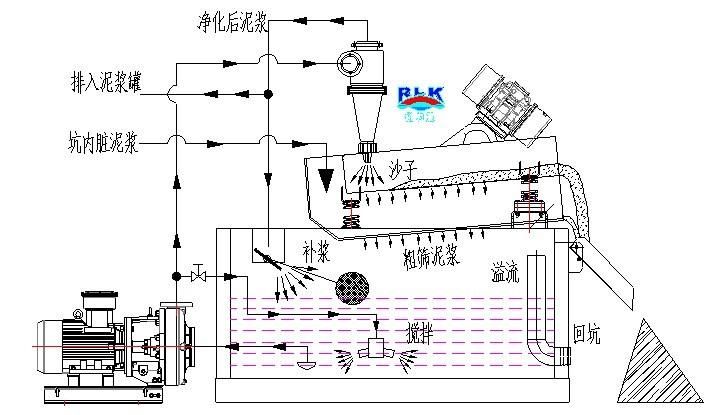

WORKING PRINCIPLE OF INTEGRATED SLURRY SEPARATION SYSTEM (Please check the work process diagram)

With the help of the pit pump, the drilling mud in the mud pit enter into the lower screen of the shale shaker, this is the first stage screen processing, large particles of solid phase is expelled, liquid mud leakage into the mud tank under the shale shaker, with the help of the slurry pump on the slurry separation system, drilling mud in the mud tank enter into the hydrocyclone for the secondary centrifugal separation, solid phase were obigger than 60 microns to separate the back to the upper deck of the top screen and screening out the back, clean mud from upper cyclone discharge, back to the undersize circulating tank for filling slurry discharge enter to the others slurry storage tank for drill rig. In the cyclone circulation tank back fill slurry pipeline set liquid level automatic balancing device, composed of floating ball and liquid level frame, when circulating tank liquid level rise, floating ball, level the flap closed, mud a lot outside, when the liquid level lower level open, turning back to the tank filling slurry, WaiPaiLiang decreases, when the liquid level to adjust the level, no longer outside, all back to the tank to fill slurry, reach the status since the circulation system. At the discharge outlet of the slurry pump, one way enters the cyclone, and a bypass pipeline is connected with the mixing nozzle pipeline in the circulating tank, and a valve is provided. When the deposition in the tank increases, the valve can be opened to backwash and stir the deposition in the circulating tank, and the slurry after mixing is pumped into the cyclone for solid-liquid separation again.The schematic diagram is as follows:

Work Process Diagram

Picture of Machine in jobsite

Picture of My factory

COMPANY PROFILE

Tianjin Ruilike Engineering Machinery Co., Ltd. was established on May 31,2012, and is located in Tianjin, China. We manufacture HDD rock drilling tools, soil sand drilling tools, mud solid control system, sewage treatment system, municipal sewage treatment system etc. According to constant development, RUILIKE is known as a brand supplier. Our corporate culture is "to forge ahead ","to be top "," do our best", adhere people-oriented, to service to create value. We supply satisfactory products to more than 200 customers in the national and global world. We consciously integrate social responsibility into production and management activities, develop green machinery products, and protect environmental resources. Ruilike keeps steady management, dedicated to creating a golden brand. RUILIKE pleasure to work with colleagues to create a supreme future.