High Quality New/Used 222mm Drilling Irrigation Well Dit Roller Cone Bits Tungsten Carbide or Steel Inserts Tri Tricone Drill Bit Tricone Drill Bit South Africa

Speedmade Industries Co., Ltd.- After-sales Service:Prodution Introduction-Dilivery Goods-Install etc

- Warranty:1 Year

- Manufacturing Process:Forging

- Surface Treatment:Polishing

- Operation Pressure:Atmospheric Pressure

- Material:Cast Steel

Base Info

- Model NO.:IADC537

- Condetion:New

- Application:["Energy & Mining, Well Drilling","Limestone,Granite,Arenaceous Shale,Dolostone,etc"]

- Video Outgoing-Inspection:Provided

- Brand Name:Speedmade

- Machine Type:Drilling Tool

- Processing Type:Forging

- Size:6 1,2 Inch

- Bearing Type:Rubber Sealed Bearing

- Usage:Well Drilling

- Machinery Test Report:Provided

- Place of Origin:China

- Thread:3 1,2"Reg

- Weight(Kg):0.3~0.7

- Suitable Formation:Soft to Meduim Formation

- Transport Package:Original Package with Wooden Cases

- Specification:20X19X33 cm

- Trademark:speedmade

- Origin:China

- HS Code:82071990

- Production Capacity:2000piece,Pieces Per Month

Description

Basic Info.

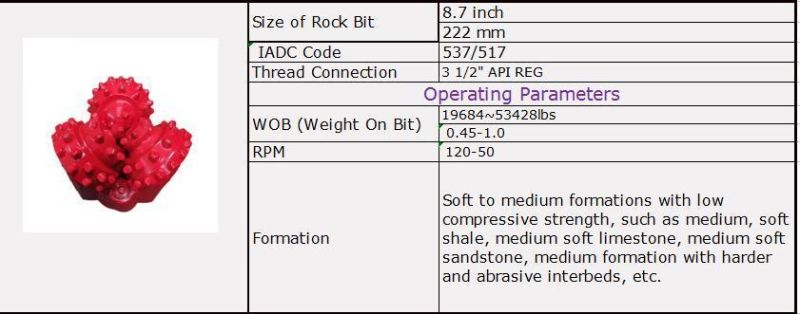

Model NO. IADC537 Condetion New Application ["Energy & Mining, Well Drilling","Limestone,Granite,Arenaceous Shale,Dolostone,etc"] Video Outgoing-Inspection Provided Brand Name Speedmade Machine Type Drilling Tool Processing Type Forging Size 6 1/2 Inch Bearing Type Rubber Sealed Bearing Usage Well Drilling Machinery Test Report Provided Place of Origin China Thread 3 1/2"Reg Weight(Kg) 0.3~0.7 Suitable Formation Soft to Meduim Formation Transport Package Original Package with Wooden Cases Specification 20X19X33 cm Trademark speedmade Origin China HS Code 82071990 Production Capacity 2000piece/Pieces Per MonthProduct Description

Product DescriptionHigh Quality New/Used 222MM Drilling Irrigation Well Dit Roller Cone Bits Tungsten Carbide or Steel Inserts Tri Tricone Drill Bit Tricone Drill Bit South Africa-Selling

| IADC | Rock formation | WOB (KN/mm) | PRM(r/min) |

| 417/427/437 | Low compressive strength, high drill-ability and extremely soft formation, like shale, clay, sandstone, conglomerate etc | 0.35~0.90 | 140~70 |

| 447 | Low compressive strength, high drill-ability and soft formation, like shale, clay, sandstone, soft limestone, salt rock, plaster etc. | 0.35~1.00 | 140~60 |

| 517 | Low compressive strength, high drill-ability and soft formation, like shale, clay, sandstone, soft limestone, salt rock, etc | 0.35~1.05 | 120~50 |

| 527 | Soft formation with low compressive, like Low compressive strength, high drill-ability and soft formation, like shale, clay, sandstone, soft limestone, salt rock, anhydrite etc. | 0.35~1.05 | 120~50 |

| 537/547 | Low compressive strength, medium hard formation with hard abrasive interlayer, like Hard shale, anhydrite, soft limestone, sandstone, dolomite with mezzanine, etc. | 0.50~1.05 | 110~40 |

| 617/627 | High compressive strength, medium hard and thick hard interlayer, like hard shale, limestone, sandstone, dolomite, etc. | 0.50~1.05 | 80~40 |

| 637/737 | High compressive strength, medium hard and high abrasive formation, like limestone, dolomite, sandstone, chert, etc. | 0.7~1.20 | 70~40 |

Cutting Structure

The wear-resistance of the teeth is enhanced with premium tungsten carbide hardfacing on the tooth surfaces for the steel tooth bit.The durability of premium tungsten carbide inserts is improved with new formulas and new techniques for insert bit

Gauge Structure

Multiple gague protection with gauge trimmers on the heel and gauge inserts on the gauge surface of the cone,tungsten carbide inserts and hardfacing on the shirttail increases gauge holding capacity and bearing life.

Bearing Structure

High precision journal bearing with two thrust faces,Balls lock the cone.Hardfaced head bearing surface.Cone bearing inlaid with friction-reducing alloy and then silver-plated.Abrasion resistance and seizure of the bearing are improved.and suitable for high rotary speed

Seal and Lubrication

The advanced metal seal package consists of two metal seals and two elastic energizers.Compressed energizers ensure good contact being kept on two sealing surfaces of metal rings by elastic force,and achieves the bearing seal.In the drilling,metal seals are relatively dynamic,and the energizers are static.This will improve the reliability and durability of bearing seal.The pressure compensator system and advanced grease can greatly increase the lubricating reliability.

Product Advantages:

a.Speedmade every new bit drilling time over 200 hours

b.Speedmade every used bit drilling time range 100~180 hours.

c. Siruite every new bit if teeth or other place are broken when you are using it in a short time,bits are all guaranteed exchange new one for free!(of cause,non-human factors)!

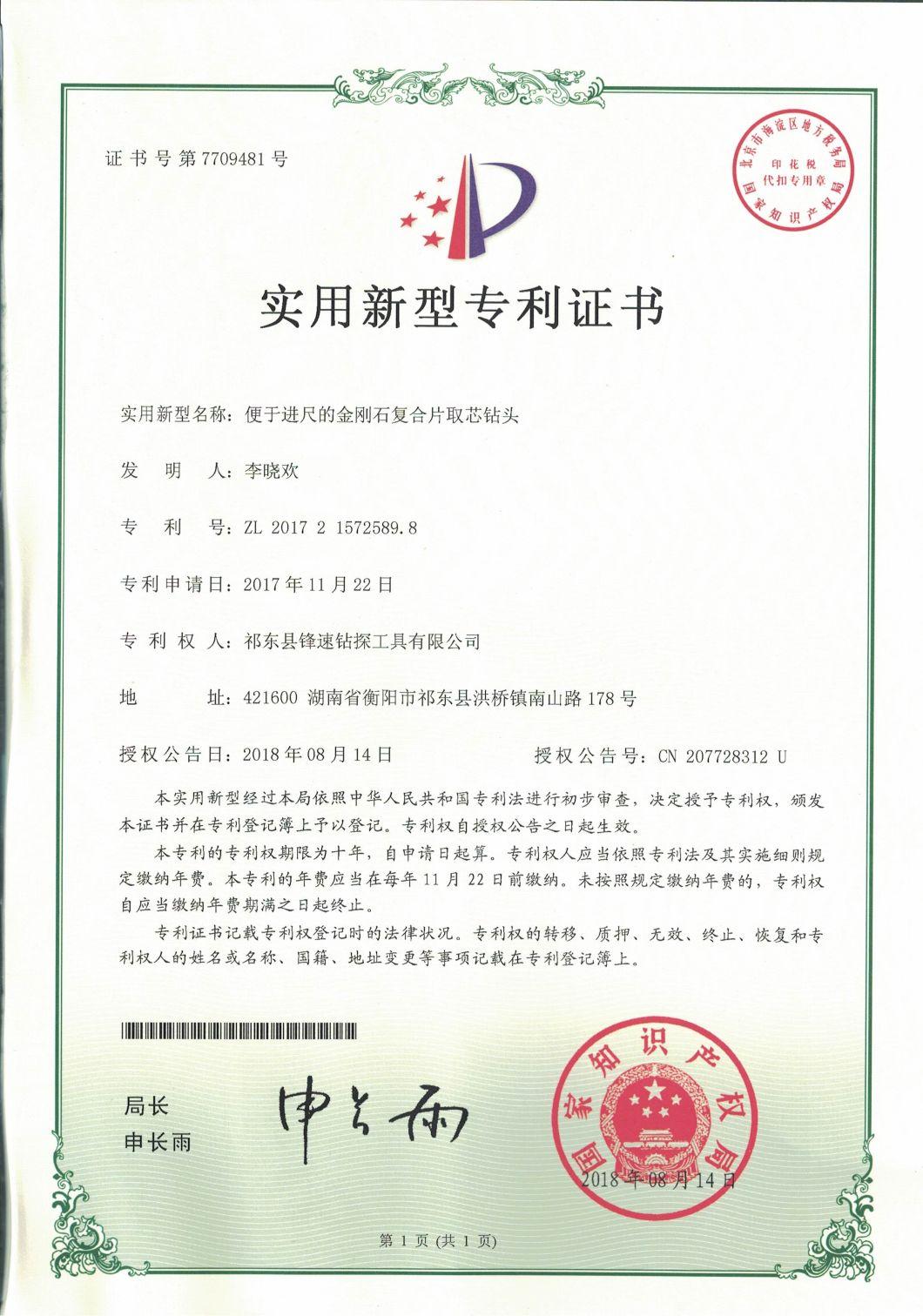

d. Siruite every bit have certification quality and specification for everyone in the box when delivery to shipping port!

e. Siruite have a big professional technical team around the world when you place a large order and need to technical support.

-WHY CHOSE US-

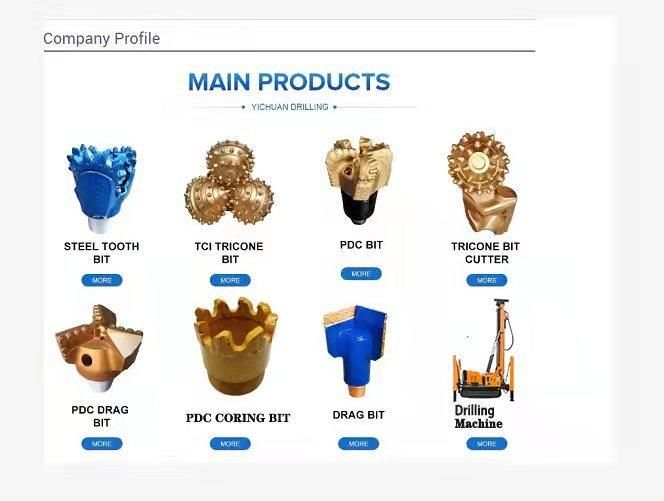

SPEEDMADEDRILL is a leader in the manufacture and development of many kinds of bits in China. We provide the best quality PDC coring drill, DTH drill, Tri drill bits etc to the market, all types of non-coring or coring drill traces. Our drill bits are used for well drilling, mining and construction contractors. Our drill bit has been tested and verified by time, with wear resistance and fast drilling speed. Different drill bits can be customized according to different rock formations. The engineering time is greatly shortened, and the maximum performance is exerted in the operation during drilling. Our products are durable and reliable. Our products are the preferred drill bits for drilling engineers in many countries because of our precise design and efficient drilling during use.

FACTORY SHOW

-PAYMENT-

DIY customization: please provide your rock formation information or detailed size drawings.

Free samples: some samples can be provided free of charge.

Trading:EXW, FOB, CFR, CIF, DDU such as.

Payment:T/T L/C,D/A,D/P,Western Union,MoneyGram.

Delivery time: normally 7-12 days